Company Description

About Brightstar Prototype CNC Co., Ltd

Brightstar Prototype CNC Co., Ltd is a trusted name in professional prototyping with 17 years of experience. Located in Guangdong, China, the company is recognized for producing high-quality prototypes for the electrical and electronic sectors, including circuit boards, microcontrollers, and component housings.

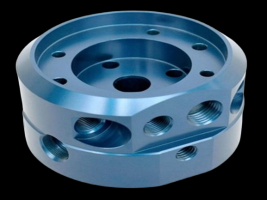

Brightstar's modern machinery and advanced manufacturing technologies enable accurate, dependable prototyping that aligns with customer expectations. The company’s services are focused on achieving accuracy and meeting detailed specifications, ensuring each prototype is suited for functional testing and design validation.

Rapid prototyping from Brightstar allows clients to test designs, check functionality, and conduct performance evaluations early in development. This process identifies potential issues, saving time and resources before large-scale production.

Brightstar works with over 100 types of materials, offering clients flexible options in metals and non-metals for product development. Their capabilities span CNC high-precision machining, 3D rapid printing, sheet metal work, vacuum casting, rapid tooling, and rapid plastic injection molding, supporting both prototypes and small-batch production.

Member Information

| Business Type | : |

|

| Founded in | : | 2007 |

| Employees | : | 11-50 |

| Member Since | : | 13 Nov 2024 |

| Membership Type | : | Free Member |

| Business Category | : | Machinery & Industrial Supplies |

Company Overview

- Manufacturer

- Supplier

- Exporter

Factory Information

Brightstar Rapid Prototyping is capable of handling more than 100+ types of manufacturable materials, metallic and non-metallic, which provides a wide range of material choices for product development in electrical and electronic industries, and specializes in a variety of Rapid Prototyping technologies, including CNC high-precision machining, 3D Rapid Printing Rapid Prototyping, Sheet Metal, Vacuum Pouring, Rapid Tooling, and Rapid Plastic Injection Molding, and supports small batch production, meanwhile, Haoshin also provides 60+ types of surface treatment services, such as anodizing, sandblasting, painting, plating... etc. to meet the demands of electrical and electronic products for appearance and functionality.

Brightstar Rapid Prototyping follows strict quality certification and ISO 9001 standards to ensure that the processed prototypes and products meet the quality requirements of the electrical and electronic industry.

Factory Image