Company Description

About Shining Jins Enterprise Co. Ltd.

Welcome to Shining Jins Enterprise Co. Ltd., an industry-leading manufacturer and designer of cold forged and headed metal components. With a history dating back to 1975, our expertise lies in supplying high-quality products to a diverse range of markets.

From light and electronic metal parts to automobile and loudspeaker components, we cater to various industries worldwide, spanning North America, Europe, Southeast Asia, and beyond.

At Shining Jins, our cold forging process sets us apart. Utilizing impact forming under high compressive force, we shape raw materials with precision and efficiency. Our cold forging presses, ranging from 110 to 1000 tons capacity, guarantee top-notch products.

Additionally, we boast an in-house sawing facility and a well-equipped machine and die shop, ensuring all our tooling requirements are met.

We take pride in our commitment to on-time delivery, with a track record of 100% punctuality and a flawless -0- PPM rejection rate. When you partner with Shining Jins, you can be assured of receiving your products as promised, thanks to our well-planned delivery strategy.

Customer satisfaction is at the core of our values. Beyond providing exceptional product quality, we excel in offering top-notch service. Our efforts to promote technological advancements for precision products have led to the establishment of factories in Taiwan and Malaysia.

At Shining Jins Enterprise Co. Ltd., we don't just manufacture metal components; we forge lasting relationships with our clients. Your complete satisfaction drives us, and we remain committed to exceeding your expectations in every endeavor.

Member Information

| Business Type | : |

|

| Founded in | : | 1975 |

| Employees | : | 11-50 |

| Member Since | : | 05 Sep 2019 |

| Membership Type | : | Free Member |

| Business Category | : | Minerals & Raw Materials |

Company Overview

- Exporter

- Manufacturer

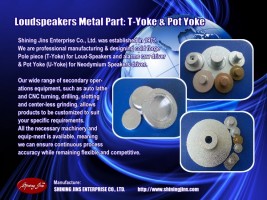

Our wide range of secondary operations equipment, such as auto lathe and CNC turning, drilling, slotting and center-less grinding, allows products to be customized to suit your specific requirements. All the necessary machinery and equipment is available, meaning we can ensure continuous process accuracy while remaining flexible and competitive.