1969 Extrusion Coating LDPE Compound - High-Speed, Thin Layer Coating Solution

1969 Extrusion Coating LDPE Compound - High-Speed, Thin Layer Coating Solution

| Country of Origin | Iran |

| MOQ | 25000 Kilogram |

| Price | USD 1 / Kilogram |

| HS Code | 1969 LEC |

| Category | Rubber & Plastic Products Plastic & Rubber Chemical |

Contact 1969 LEC 1969 Extrusion Coating LDPE Compound supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

1969 LEC 1969 EXTRUSION COATING LDPE COMPOUND

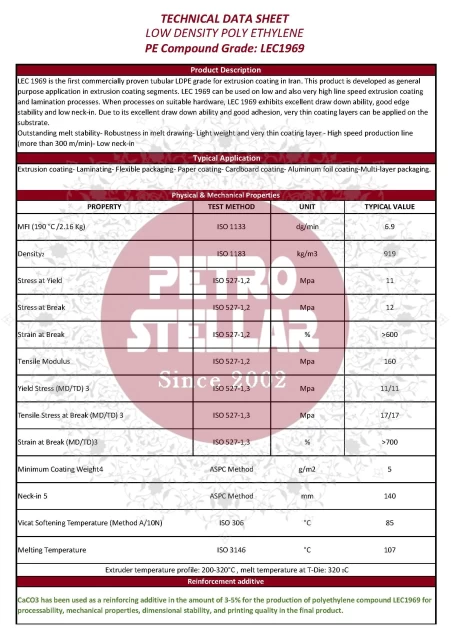

1969 LEC 1969 Extrusion Coating LDPE Compound stands as the pioneering tubular LDPE grade for extrusion coating in Iran. Designed for versatile application across extrusion coating segments, this compound delivers exceptional draw-down ability and adhesion, enabling the application of very thin coating layers.

Reinforcement additive

CaCO3 has been used as a reinforcing additive in the amount of 3-5% for the production of polyethylene compound LEC1969 for processability, mechanical properties, dimensional stability, and printing quality in the final product.

Product Available Form & Packaging - This product is packed in 25 Kg PE bags.

Storage

Polyethylene resins should be protected from direct sunlight and/or heat during storage. The storage location should also be dry, dust free and the storage temperature should not exceed 50°C. It is also advisable to process polyethylene resins (in pelletized or powder from) within 6 months after delivery, because excessive aging of polyethylene can lead to a deterioration in quality. Arya Sasol Polymer Company would not give any warranty to bad storage conditions which may lead to quality deterioration such as color change, bad smell and inadequate product performance.

Recycling

Recycled resins may have previously been used as packaging for, or may have otherwise been in contact with, hazardous goods. Converters are responsible for taking all necessary precautions to ensure that recycled resins are safe for continued use. "

Other Details

•Conveying equipment should be designed to prevent the accumulation of fines and dust particles. These particles can, under certain conditions pose an explosion hazard. We recommend that the conveying system will be equipped with adequate filters and be operated and maintained in the way that ensure no leaks develop.

•The resin is manufactured to the highest standards, but special requirements apply to certain applications such as food end-use contact and direct medical use. Specific information on regulatory compliance can be requested via customer.

•The above data are typical laboratory averages. They are intended to serve as guide only.

• The product is not classified as a hazardous material

• Typical Values : not to be construed as specifications.

PETROSTELLAR, based in Iran, is a leading manufacturer and exporter, providing this product to meet the high demand in extrusion and coating industries worldwide.

Product Usages

LEC 1969 is the first commercially proven tubular LDPE grade for extrusion coating in Iran. This product is developed as general purpose application in extrusion coating segments. LEC 1969 can be used on low and also very high line speed extrusion coating and lamination processes.

When processes on suitable hardware, LEC 1969 exhibits excellent draw down ability, good edge stability and low neck-in. Due to its excellent draw down ability and good adhesion, very thin coating layers can be applied on the substrate.

Outstanding melt stability- Robustness in melt drawing- Light weight and very thin coating layer - High speed production line (more than 300 m/min)- Low neck-in"

Extrusion coating- Laminating- Flexible packaging- Paper coating- Cardboard coating- Aluminum foil coating-Multi-layer packaging.

Product Keywords: high-speed extrusion coating LDPE compound, buy LDPE extrusion coating compound, low neck-in extrusion coating, LDPE compound supplier from Iran, extrusion coating thin layer solution, high-speed LDPE compound supplier, wholesale LDPE extrusion compound, polyethylene extrusion coating supplier

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +9891222xxxxx |

Supplier Info:

PETROSTELLAR

Tehran, Iran

Tehran, Iran

Year Established: 2002

Business Type:

- Manufacturer

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: PETROSTELLAR

Related Products

-

- Price: USD 1.2 / Square Meters

- MOQ: 1000 Square Meters

-

- Price: USD 300 / Metric Ton

- MOQ: 1 Metric Ton

- 2420H LDPE Film Grade Compound

- ABS Plastic Sheet

- LLDPE, LDPE, HDPE, MDPE, XLPE

- Ldpe Film Scrap

- Rubber Coal Mining Conveyor Belt

- High reputation hydraulic rubber hose

- Lldpe 3840u

- Aluminum Extrusion 6063 Scrap

- Aluminum Extrusion 6063

- Floating Solar Plant Floating Solar System

- CPVC compound

- Lldpe Roto regrind scrap