Calcium Chloride Production Line for Efficient Anhydrous Calcium Chloride Manufacturing

Calcium Chloride Production Line for Efficient Anhydrous Calcium Chloride Manufacturing

| Brand | Banghua |

| Country of Origin | China |

| MOQ | 1 Units |

| Price | USD 250000 / Units |

| Category | Machinery & Industrial Supplies Chemical Machinery & Parts |

Contact Calcium Chloride Production Line supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

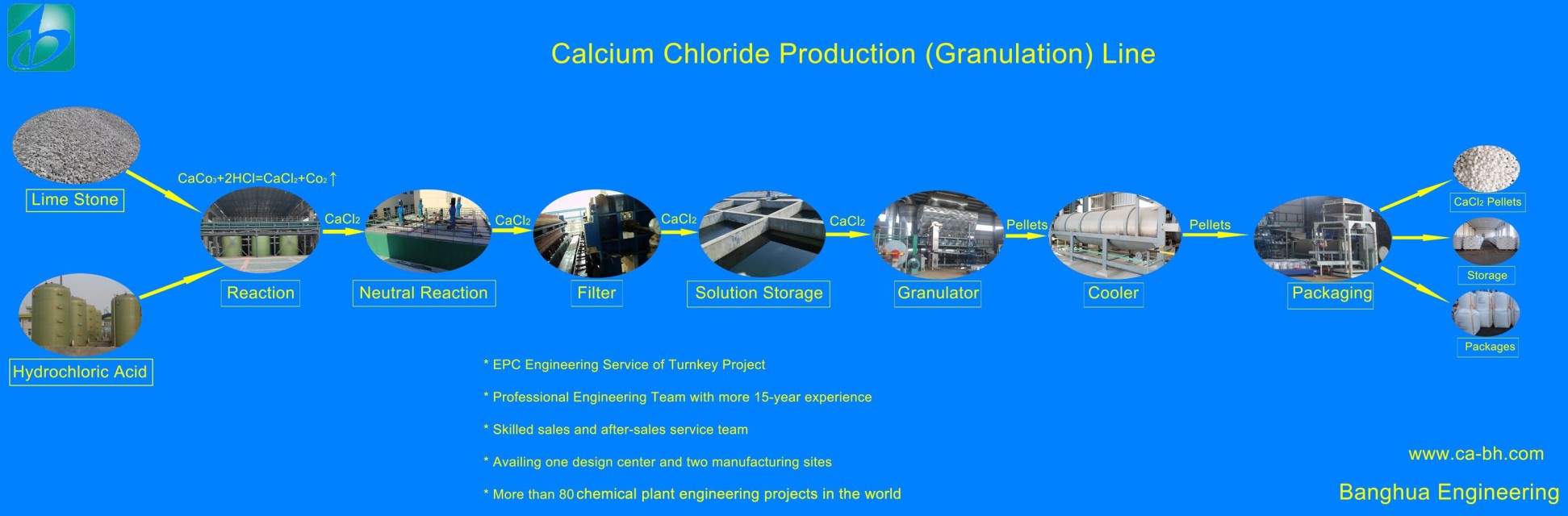

Calcium Chloride Production Line

The Calcium Chloride Production Line is a complete system for producing anhydrous calcium chloride. It includes reaction preparation, fluidized bed granulation, and final cooling and packaging. With a production capacity of over 20,000 tons per year, this line produces uniform, high-quality granules. It uses low power and has a low gas consumption. You can get this from Banghua International Granulation Engineering Co.

I. Product description

Complete calcium chloride granulation line starts from calcium chloride reaction preparation to final spray granulation for producing anhydrous calcium chloride. It mainly includes three parts:

1. Reaction section

2. Fluidized bed drying granulation

3. Cooling and packaging

II. Techincal parameters:

- Concentration of calcium chloride solution: 35-55%

- Calcium chloride product: 94%

- Temperature of solution: <60ºC

- Capacity: ≥20000 tons per year

- CaCl2 concentration: 35%-55%

- CaCl2 concentration: 94%

- Power voltage: 380V (±5%) etc

- Frequency: 50/60Hz (±1%)

- Power consumption: 115~125 KWh

- Natural gas consumption: 180~190m3

More specific details, please feel free to contact.

Product Usages

The atomized solution is sprayed into the fluidized bed granulator, and atomized droplets directly touch with the fluidized material layer (crystal nucleus layer). Before dehydration, the droplets adhere to the surface of crystal nucleus, and form local infiltration layer. Meanwhile, the relatively tiny powders adhere to the local infiltration layer, of which the water is removed gradually.

Because of water removal, the powder and droplets become lamellar and adhere to the surface of crystal nucleus. So, the crystal nucleus become larger and larger, with this process repeated. In the fluidized bed granulation area, the crystal nucleus is adhered to water droplets constantly, crystal nucleus impact with each other, and water removes gradually, all these make the granules grow bigger gradually, layer by layer, and in uniform, also synchronized with the evaporation of the water.

So, this method ensures the uniform and compact structure of the granules, also increase its intensity. Its working principle is mostly accumulated coating granulation, few is reunited granulation

Product Keywords: Calcium chloride production process, buy calcium chloride for sale, calcium chloride suppliers from China, calcium chloride fluidized bed supplier, competitive price calcium chloride, calcium chloride manufacturer in China, best calcium chloride supplier, buy calcium chloride online

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8615910xxxxx |

Supplier Info:

Banghua International Granulation Engineering Co.,

Shandong, China

Shandong, China

Year Established: 2008

Business Type:

- Manufacturer

- Supplier

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Banghua International Granulation Engineering Co.,

Related Products

- Alfa Laval Recondition Oil Separators Purifier Centrifuge

- 50kg Dry Ice Maker for Blast Cleaning

- Oil Clarification Tubular Centrifuge

- High Speed Tubular Bowl Centrifuge

- Process Control Instruments

- Portable Concrete Vibrator Rods

- Aerated Septic System

- Engine oil regeneration plant

- Wiped film distillation equipment

- Alfa Laval Plate Heat Exchanger

- PU toys production line sponge ball injection conveyor machine

- Rotary dryer dries 100+ tons of coal slimes