Charcoal Waste Briquette Machine

Charcoal Waste Briquette Machine

| Country of Origin | China |

| MOQ | 1 Sets |

| Price | USD 8500 / Sets |

| Category | Machinery & Industrial Supplies Farming Machinery |

Contact Charcoal Waste Briquette Machine supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

Charcoal Waste Briquette Machine

Introduction:

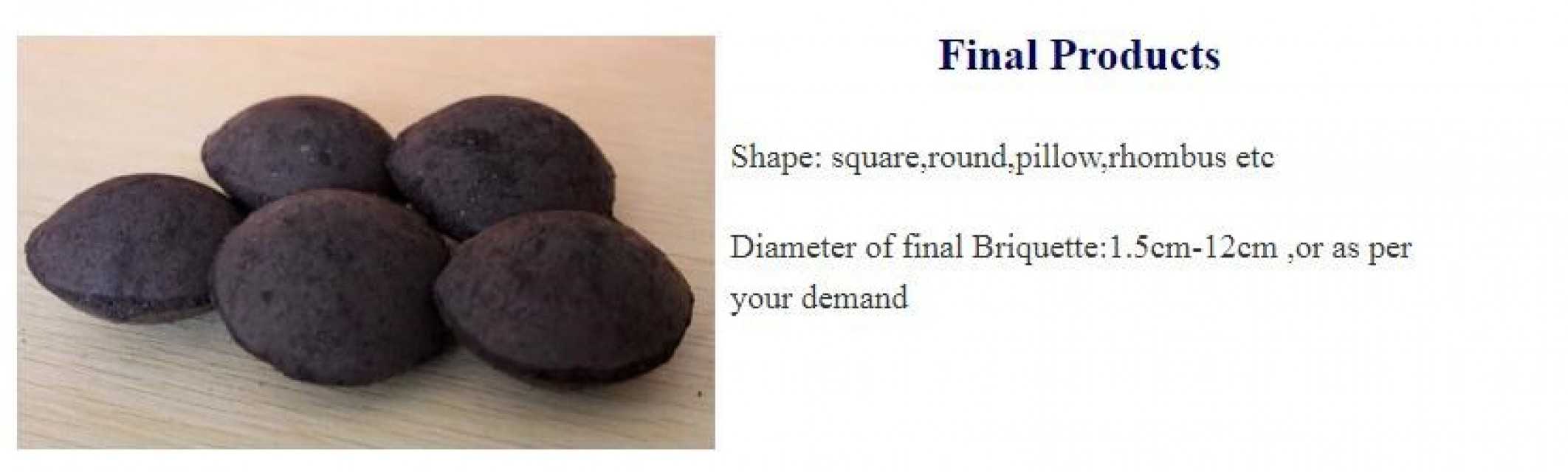

Charcoal waste briquette machine is used for coal fines, ore fines, desulfurization gypsum, phosphor gypsum, coke fines, iron fines, mill scale, fluorite power, manganese ore fine sand other material fines into briquette, which can be made to round ball shape, oval shape, pillow shape, square shape and so on,or can be manufacture as customer requirement. This machine is widely used in refratory industry,coal industry,and metallurgy industry. Charcoal waste briquette machine, the main rollers adopt high-quality manganese steel materials(65Mn/9Cr2Mo), greatly improving the wear resistance and pressure ability, make the machine has a long service life, has been widely used in recent years.

Notice:

(1) The particle size of raw material should be between 0-5mm.

(2) Charcoal waste briquette machine feeding material can not contain impurities, especially large metal. such as nails, or iron bolts and nuts, rocks, etc. it is easy to damage roller and spindle.

(3) The feeding speed of whole production line should be stable, even, and make sure workloads is also stable so as to get high efficiency of production.

Production Line Work-flow:

The charcoal waste briquette machine production line generally includes raw material batching, grinding and mixing, briquetting and drying.

(1) The different kinds of raw material is evenly mixed by batching machine in the first step.

(2)These machine goes into wheel grinding mixer or double shaft mixer machine to further mixing, at this moment, the binder material will be put into together.

(3)The mixture material will enter into roller briquette machine for molding, and discharged various briquette shape according to customer requirement.

(4)Because the fresh briquette contents moisture, couldn’t be used directly. The mesh belt dryer or chain belt dryer, as well as vertical dryer will give them completely drying process. The final dried briquette can be smelted, transported or heating directly.

| Payment Terms: | 30% T/T in advance, 70% before shipment or against B/L copy |

| Packaging Info: | Seaworthy packing as per export container rules, bigger items loose stuff in container and small parts will be tied up in a bundle put into steel boxes or plywood boxes. Delivery will be arranged based on busy or low producing season in our factory, |

| Delivery Info: | 30-35 Working Days |

Product Specification

| Brand Name : | Shisheng Machinery |

| Model No : | XM650 |

| Material : | Carbon Steel |

| Color : | Black |

| Size : | 1850*1780*1950mm |

| Capacity : | 4-5t/h |

| Roller Shape : | Oval/Pillow/Square/Round |

| Motor Power : | 37kw |

| Aftersales Service : | Dispatch Engineer to Overseas Installation |

| Beforesale Service : | Sample Material Testing Machine on Site |

| Visiting Service : | Local Airport Pick Up |

| Business Type : | Manufacturer |

| Briquetting Type : | Wet Briquetting |

| Roller Diameter : | 650mm |

| Roller Width : | 470mm |

| Pressure Type : | Mechanical Pressure |

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8615978xxxxx |

Supplier Info:

Zhengzhou Shisheng Machinery Co. Ltd.

Henan, China

Henan, China

Year Established: 2014

Business Type:

- Exporter

- Manufacturer

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Zhengzhou Shisheng Machinery Co. Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 9000 / Units

- MOQ: 1 Units

-

- Price: USD 2250 / Sets

- MOQ: 1 Sets

- Slope Screen Type Pig Manure Dewatering Machine

- 0.75kw Peanut Harvester Picker Machine

- Farm Tractors

- Farm Machine Gear Drive 170F Gasoline Mini Tiller Cultivator

- Planting Machine (HX-A060)

- Double Screw Palm Oil Pressing Machine

- Mini palm oil press machine for making red palm oil

- Agricultural Shredder Machine

- Maize Corn Silage Beet Pulp TMR Round Baler Machine

- Multifunctional ridge machine

- Charcoal Pieces Briquette Machiine

- Wool Industrial Washing Machine