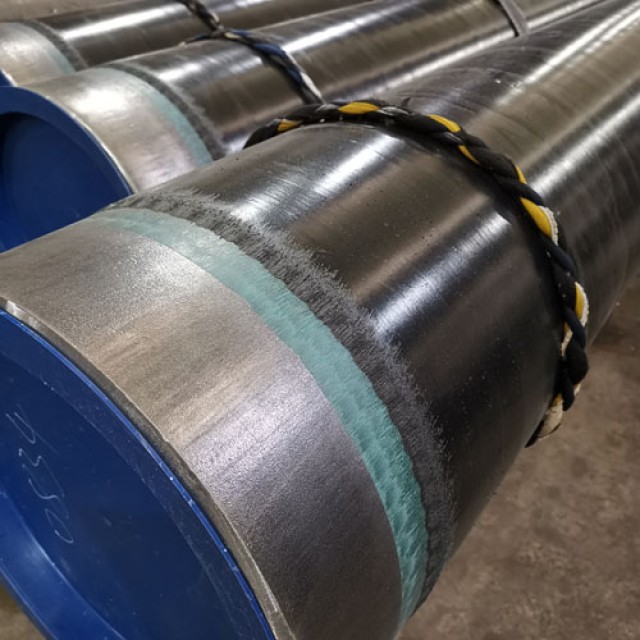

FBE Anti-corrosion 3LPP HDPP 2PP 3PP Coating Seamless Pipe for Fluid Transport

FBE Anti-corrosion 3LPP HDPP 2PP 3PP Coating Seamless Pipe for Fluid Transport

| Country of Origin | China |

| MOQ | 1 Tons |

| Price | USD 740 / Tons |

| Category | Machinery & Industrial Supplies Metallurgy Machinery & Parts |

Contact FBE Anti-corrosion 3LPP HDPP 2PP 3PP Coating Seamless Pipe supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

FBE Anti-corrosion 3LPP HDPP 2PP 3PP Coating Seamless Pipe

FBE Anti-corrosion 3LPP HDPP 2PP 3PP Coating Seamless Pipe is designed to meet the needs of multiple industries, including oil, gas, water transport, and wastewater treatment. Coated with layers of anti-corrosion materials, including FBE, 3LPP, and HDPP, these pipes offer superior protection against rust and damage.

This seamless pipe is available in various grades such as Q195-Q345 and comes in lengths ranging from 6 to 12 meters. The pipes are manufactured according to international standards like API 5L and DIN EN 10305, ensuring quality and safety. With a thickness range of 2.9 to 60 mm, the pipes cater to different industrial needs.

Specifications

- Section Shape: ROUND

- Surface Treatment: 3LPP/3PP/2LPP/2PP coating

- Tolerance: ±1%

- Oiled or Non-oiled: Non-oiled

- Invoicing: by actual weight

- Place of Origin: Inner Mongolia, China

- Alloy Or Not: Non-Alloy

- Standard: DIN

- Grade: 3LPP/3PP/2LPP/2PP

- Delivery Time: 15-21 days

- Application: Gas, Oil, Water Transport

- Special Pipe: API Pipe

- Thickness: 2.9 - 60 mm

- Length: 12M, 6m

- Certificate: API, ce, ISO9001

- Processing Service: Welding, Punching, Cutting, Bending, Decoiling

- Product name: 3 Layer Polypropylene Anti-corrosion Coated Seamless Steel Pipe

- Length: 5.8-12m

- Usage: gas, water, oil transport

- 2LPP/3LPP coating standard: DIN30678, NF A49-711 etc.

- Standard: API 5L, DIN EN 10305, GB/T 12771-2000

- Grade: Q195-Q345,10#-45#

- Type: Seamless Steel Pipe

Inner Mongolia Rational Industry Limited (IMRI), based in Inner Mongolia, China, offers competitive pricing and dependable delivery for large orders. Whether used in oil and gas pipelines or water supply systems, this product delivers high performance. IMRI is committed to maintaining the quality and integrity of every batch, serving both international and domestic markets.

Product Usages

Uses -

1.Oil and Gas Industry: Anti-corrosion coated pipes are used in the oil and gas industry for oil pipelines, gas pipelines and oil well steel pipes to protect the pipes from corrosion and damage.

2.Chemical Industry: Anti-corrosion coatings are commonly used in chemical transportation pipelines and storage tanks in the chemical industry to protect the pipelines and tanks from corrosive media.

3.Water supply system: Anti-corrosion coating technology is also widely used in water supply pipelines, sewerage pipelines and marine engineering to ensure the safety of water quality and the long-term stable operation of pipelines.

4.Wastewater treatment: anticorrosion coated pipes are also used in wastewater treatment discharge pipes, sewage pipes, and biopond corrosion prevention projects to prevent corrosion and extend the service life of pipes.

5.Agricultural irrigation: anti-corrosion coated pipes are also used in networks such as agricultural irrigation pipes, deep well pipes and drainage pipes to improve the durability and corrosion resistance of the pipes.

6.Marine engineering: pipeline engineering fields such as marine water transfer piling apply to high-rise building water supply, heat network heating, water works, gas transmission, buried water transmission and other pipelines, anti-corrosion coated pipes play a key role in these applications.

7.Electricity and communication: applicable to electric power, communication, highway and other cable-covered pipeline protection.

8.Industrial buildings: anti-corrosion coated pipes are also widely used in anti-corrosion construction operations of equipment and pipes in civil and general industrial buildings

Special environments: in polar and marine environments, the anti-corrosion coating is also widely used.

9.Special environments: pipelines laid in harsh environments such as poles and oceans, as well as the heating of oil products to be transported to make the pipeline temperature rise in the environment, the performance of the coating puts forward more requirements, so the anti-corrosion coating pipeline in these special environments is also very important.

10.Inner wall anticorrosion: In order to prevent corrosion in the pipe, reduce frictional resistance, improve the transmission and coated on the inner wall of the pipe film, commonly used coatings are amine-cured epoxy resin and polyamide epoxy resin.

Product Keywords: FBE, Anti-corrosion, 3LPP, HDPP, 2PP, 3PP, Coating Seamless Pipe, FBE anti-corrosion coated seamless pipe for sale, 3LPP HDPP coating pipe wholesale, buy FBE seamless steel pipe, anti-corrosion pipe for oil and gas transport, bulk FBE anti-corrosion coating pipe, seamless pipe for water transport, price of anti-corrosion coated seamless pipes

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8613847xxxxx |

Supplier Info:

Inner Mongolia Rational Industry Limited. (IMRI)

Nei Monggol, China

Nei Monggol, China

Year Established: 2019

Business Type:

- Supplier

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Inner Mongolia Rational Industry Limited. (IMRI)

More Products From This Supplier

Related Products

- Titanium Sheet & Plate

- API 5L X52 steel pipe

- Welding White Hourglass Pipe

- Elbow WPB A234

- 50kN Plastic PVC Pipe Ring Stiffness Testing Machine

- Indian Pipe Fittings

- Bluslot Drill Pipe Screen

- Auto Parts Custom Small Quantity Injection Molding

- OD-13.5mm * W.T4mm * L4500mm Oxygen Lance Pipe

- Globe Valve

- Rockwool Pipe Insulation

- Rotating pipe joint saturated steam swivel joint