Fill-and-Pack Bag in Box Line for 3-25L BiB - Wholesale Supplier

Fill-and-Pack Bag in Box Line for 3-25L BiB - Wholesale Supplier

| Country of Origin | China |

| MOQ | 1 Sets |

| Price | USD 19999 / Sets |

| Category | Machinery & Industrial Supplies Packaging Machinery |

Contact Fill-and-Pack Bag in Box Line for 3-25L BiB Filling and Packaging supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

Fill-and-Pack Bag in Box Line for 3-25L BiB Filling and Packaging

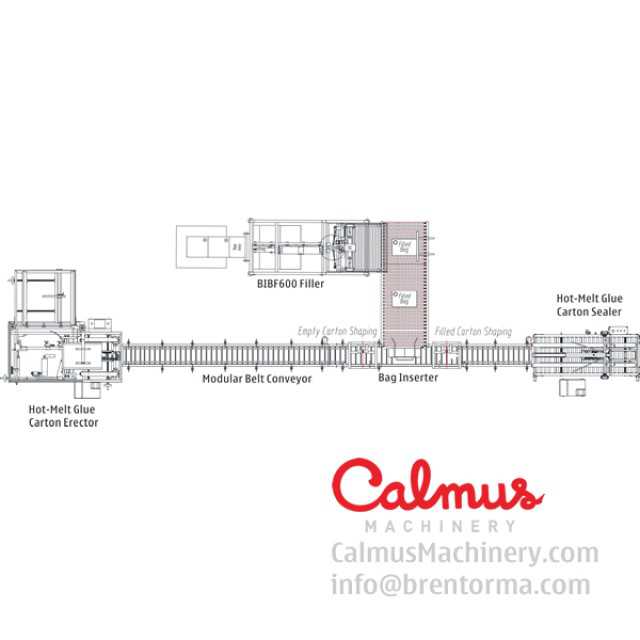

Fill-and-Pack Bag in Box Line for 3-25L BiB Filling and Packaging is a state-of-the-art, fully-automatic system designed to package liquids efficiently and safely.

This line includes a Bag-in-Box filling machine, carton erector, bag inserter, box sealer, and conveying systems, all made from high-quality Grade 304 stainless steel with fluid-contact parts in Grade 316L stainless steel. The use of renowned global components ensures durability and reliability.

The Fully-automatic Filling and Packaging Line includes:

1. Fully-automatic Bag-in-Box Filling Machine

2. Hot-Melt Glue Carton Erector

3. Bag Inserter

4. Hot-Melt Glue Box Sealer

5. Conveying Systems

The whole line is fully-automatic. Grade 304 stainless steel construction and grade 316L stainless steel fluid-contact parts. World famous brands of key components and many are imported. Made in China, but built at high quality level.

Procedures of the whole line:

1) Automatically feed bags.

Bags Feeding of Bag-in-Box Filling and Packaging Line BIBFPL600

2) Automatically pull cap, fill, cap and cut bags apart.

Bag Filling of Bag-in-Box Filling and Packaging Line BIBFPL600

3) Automatically erect cartons and seal bottoms with hot melt glue.

Carton Erecting of Bag-in-Box Filling and Packaging Line BIBFPL600

4) Automatically insert filled bags in boxes.

Bag Inserting of Bag-in-Box Filling and Packaging Line BIBFPL600

5) Automatically seal the box tops with hot melt glue.

Box Sealing of Bag-in-Box Filling and Packaging Line BIBFPL600

1. Fully-automatic Bag in Box Filling Machine

The Fully-automatic Bag in Box Filling Machine is designed for filling spouted bags with a wide range of liquids like drinking water, post mix syrup coke, edible oil and beverage. It features fully-automatic by employing PLC and touch screen control system. The whole process of continuous bags feed, decapping, vacuumization (optional), nitrogen injection (optional), filling, capping, cutting apart from continuous bags and transiting to the conveyor can be completed automatically, no human operation required.

This filling machine can cap various spigots including Vitop and Scholle's. It is designed with CIP (Clean in Place) function and pipeline connection. Grade 304 stainless steel body and 316L stainless steel fluid-contact parts.

Features:

1) Fully-automatic, WEB type bags fed.

2) Easy to use. The touch-screen control system makes operation easy.

3) An electromagnetic or turbine flowmeter employed improves filling precision and truly achieves the quantitative filling.

4) An air filter employed brings clean air to the filling space.

5) Grade 304 stainless steel body and 316L stainless fluid-contact parts.

6) Filling a different capacity bag acceptable only by changing the setting.

7) Options of vacuumization and nitrogen injection available for specific products use.

Specifications:

Applicable bags: pre-cut continuous module or WEB type bags, spout-fitted, 3-25 litres. (Spout is called Gland or Flange too.)

Filling capacity:

450-510 bags/hour for 5 litres

360-400 bags/hour for 10 litres

250-270 bags/hour for 20 litres

Power: 1.0 kW

Compressed air: 6-8 bar, 500 NL/min

2. Carton Erector (Erecting carton and sealing bottom)

Erecting capacity: 6-7 cartons/min

Grade 304 stainless steel construction

Hot Melt Glue System: Nordson

3. Bag Inserter (Inserting filled bags in cartons)

Inserting capacity: 15 bags/min

Grade 304 stainless steel body

4. Hot Melt Glue Box Sealer (Closing and sealing top)

Sealing capacity: 10 cartons/min

Grade 304 stainless steel construction

Hot Melt Glue System: Nordson

5. Conveying Systems

Grade 304 stainless steel

| Payment Terms: | By T/T or L/C |

| Packaging Info: | Packed with Plywood |

| Delivery Info: | 90 Days |

Product Specification

| Brand Name : | Calmus |

| Model No : | BIBFPL600 |

| Material : | 316L/304 Stainless Steel |

| Applicable Bags : | WEB Type Bags, Spout-fixed, 3-25L |

| Filling & Packaging Capacity : | 360-400BPH for 10L |

| CIP Pipeline Included : | Yes |

Product Usages

The Fill-and-Pack Bag in Box Line for 3-25L BiB Filling and Packaging is used to package liquids into spouted bags with precision and efficiency.

Its fully-automatic operation ensures consistent performance, making it ideal for large-scale production in industries packaging water, syrups, and oils. This system minimizes manual intervention, ensuring smooth operation and maintenance while maximizing productivity.

Product Keywords: Bag in box line, bag in box packaging line, bag in box filling line, Fill-and-Pack Bag in Box Line supplier, 3-25L BiB Filling Line wholesale, automatic Bag in Box packaging line, Bag in Box machinery B2B, BiB Filling Machine rate, Fill-and-Pack Bag in Box manufacturer, BiB Packaging Line price, China Bag in Box supplier

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +86xxxxx |

Supplier Info:

Calmus Machinery (Shenzhen) Co. Ltd.

Guangdong, China

Guangdong, China

Year Established: 2008

Business Type:

- Manufacturer

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Calmus Machinery (Shenzhen) Co. Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 1500 / Sets

- MOQ: 1 Sets

- Personal Belonging Bag

- Transparent Film 3D Packaging Machine

- HUILIDE Space Feeder

- Automatic V Grooving Machine

- Radio Shuttle Racking With Pallet

- Full Automatic Trimming, Embossing, Perforating Rewinder

- B2 Luggage Wrapper Machine

- High speed Carton Erector for E-commerce

- Best Rope Coiling Machine

- Easy Operate Auto Blade Bending Machine

- Paper film slit spooling machine

- RTM2610S Digital Dew Point Meter Separate Sensor