High-speed M35 Steel Round Bar Sheet Plate For Cutting Tools

High-speed M35 Steel Round Bar Sheet Plate For Cutting Tools

| Country of Origin | China |

| MOQ | 1 Short Ton |

| Price | USD 1081 / Short Ton |

| HS Code | M35 Steel |

| Category | Minerals & Raw Materials Iron & Steel Copper |

Contact M35 High-Speed Steel Round Bar Sheet Plate supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

M35 Steel Round Bar Sheet Plate Heat Treatment Processing technology

M35 Steel Round Bar Sheet Plate Heat Treatment 1.3243 Steel Forging Technology. The alloy element content of M35 steel is more than 22%, higher than that of M2 steel, about 30%. Its forging is difficult. You need to pay attention to it, just as you would with M42 steel forging.

First of all, preheat it fully. The heat temperature is 1120℃1150℃. The temperature at the beginning is 1000℃1050℃, and the ending must be higher than 899℃. After forging, it should cool slowly and anneal on time to prevent cracking.

M35 Steel Annealing Process

If you case it up for the annealing after the forging, you will get a better result. If you can not do that, make it cold to the indoor temperature then make it in. About the annealing process, just put it in the stove with the temperature which is lower than 500℃.

Then heat to 840-860℃, keep the temperature for four to five hours. Furnace cooling to 500℃ below than out of it. It is cooling slowly in the annealing furnace. After the annealing, its hardness is lower than 255HB.

In order to prevent oxidative decarburization happen, the annealing should be careful. And there is an easy way can do that. Just put some wood dust to the annealing furnace.

Notice for Quenching and Tempering

- Preheat two times: 600℃, 860℃. And the time of preheating is twice the time of heating.

- The request of quenching is 10-12s/mm.

- Needs the step hardening: 600℃→260-280℃→air cooling.

The temperature of secondary hardening is 535-540℃ around. The hardness is bigger than 68HRC for after tempering. But the factories do not want the hardness of cutting tool is more than 68HRC due to the request for production. So it always is been tempering.

As we can see from the table, the best temperature for quenching is in the range of 1215-1225℃. In this condition, it is suitable for annual cutting tools. Its hardness is about 67-67.5HRC. It satisfies the needs of high-speed steel high-speed steel for high strength, high hardness, and high wear resistance.

M35 steel quenched at a temperature below 1190℃ is a good material for cold work dies and low-speed cutting tools. If it has been quenched at a temperature higher than 1230℃, it will have a great red hardness.

It will be a good choice for turning tools and etc. Quenching it in that way will cause overheating. But it is not a trouble, the key is to control it in the right way. Some cutting tools are overheating to be more useful.

Notice

In China, we have been focusing on the steel industry for decades, as a professional supplier, a powerful steel factory, advanced technology, high-quality steel, we have our own cutting and processing facilities.

Specific specifications can be customized according to your needs. Provide reliable M35 high speed steel products as well as other high speed steels, please contact us for any needs of high speed steel M35 steel.

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Packaging Info: | According to your needs |

| Delivery Info: | Shenzhen,Tianjin,Shanghai.China |

Product Specification

| Model Number : | M35 Steel |

| Color : | According to your needs |

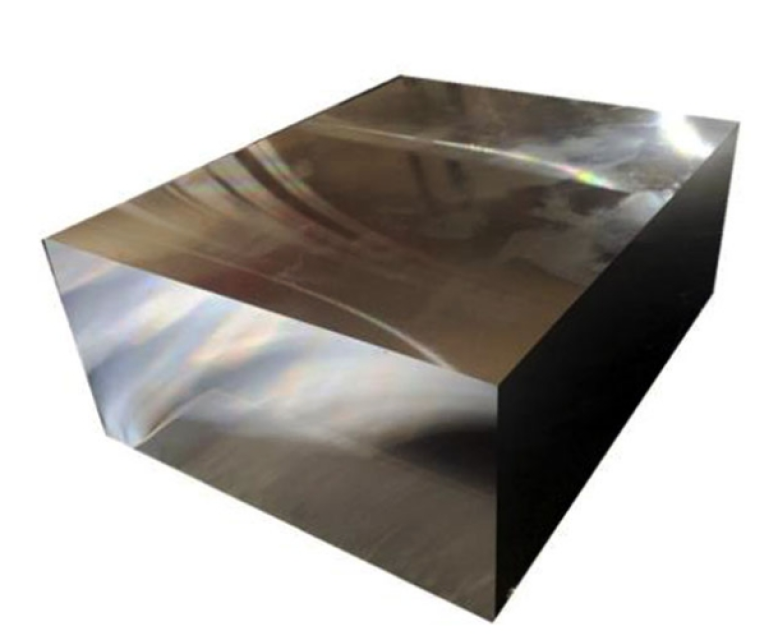

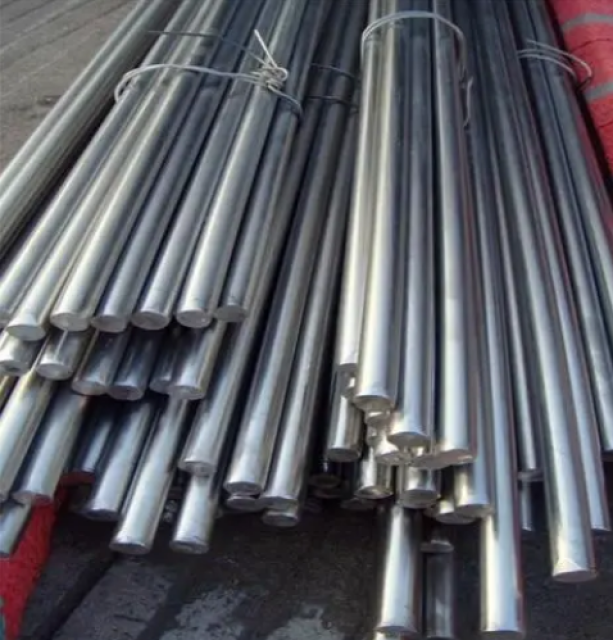

| Size : | Thickness: 1.3-200mm; Width: 200-810mm; Length: Can be customized; Other specifications can be customized. |

| Weight : | According to your needs |

| Style : | High Speed Steel |

| Technology : | According to your needs |

| Standard : | AISI / ASTM / SAE |

| Grade : | M35 Steel |

Product Usages

M35 cobalt-containing high-speed steel is cheaper and easier to process. Through proper heat treatment, it can obtain high hardness (HRC67-70), high red hardness (625℃ 4 hours, HRC63-65) and high wear resistance.

Toughness and bending strength are not lower than ordinary high-speed steel, which can overcome early damage such as mold edge collapse and cracking. Characteristics and application: This steel is tungsten steel high speed.

It is suitable for manufacturing various wear-resistant and impact-resistant tools for strong cutting, advanced punching dies, screw dies, tools that require toughness and complex shapes, reamers, milling cutters, iron heads, punches, etc. The main uses are hobs, broaches, and end mills.

Product Keywords: M35 high-speed steel price, wholesale rate M35 steel, manufacturer exporter supplier M35, buy M35 steel b2b, M35 steel sheet plate supplier, M35 steel round bar bulk price, M35 steel heat treatment supplier, high-speed steel supplier China.

Product Images

Product Video

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8617777xxxxx |

Supplier Info:

Songshun Mould Steel Co., Ltd.

Guangdong, China

Guangdong, China

Year Established: 2009

Business Type:

- Manufacturer

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Songshun Mould Steel Co., Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 1000 / Kilogram

- MOQ: 100 Kilogram

-

- Price: USD 12000 / Tons

- MOQ: 1 Tons

-

- Price: USD 8500 / Tons

- MOQ: 3 Tons

- Steel Pipe

- Indolift Alloy Steel Chain

- Duplex Stainless Steel Sheet & Plate

- Molybdenum High Speed M2 Steel

- API 5L X42 Steel Pipe

- Stainless Steel Scrap

- SSAW Steel Pipe

- Duplex Steel Pipe Fitting

- Prepainted Galvanized Steel Coil Ppgi Aluminium Steel Coil

- Zn-5%Al-mischmetal alloy-coated steel strands (galfan)

- Steel plate factory | Low Cost hot rolled steel plate factory

- High Quality ASTM Steel Rod 410 420 416 Stainless Steel Round Bar