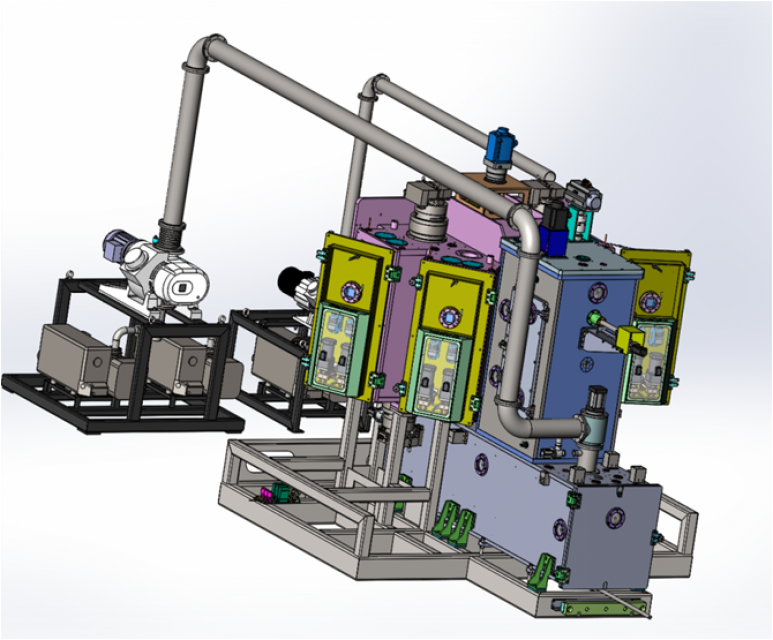

Smart Sputtering-Optical Coater with auto loading & unloading system

Smart Sputtering-Optical Coater with auto loading & unloading system

USD 1400000 / Units

| Country of Origin | China |

| MOQ | 1 Units |

| Price | USD 1400000 / Units |

| Category | Machinery & Industrial Supplies Metal Processing Machinery |

Contact supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

Smart Sputtering-Optical Coater with auto loading & unloading system

Smart Sputtering-Optical Coater with auto loading & unloading system

(Specially designed for mobile shell coating)

Smart Sputtering-Optical Coater uses MF magnetron sputtering technology to coat a multilayer optical film layers by aid of the activating and cleaning functions of MF or RF plasma device.

More recently, advances in sputtering technology have resulted in coating equipment capable of producing complex optical coatings of more than 200 layers. Advanced plasma reactive sputtering (APRS) uses MF dual-magnetrons and achieves consistent, repeatable rates of deposition with highly predictable thin-film optical characteristics. Armed with accurate optical and time-based layer monitoring techniques, APRS is capable of producing complex filters with spectral performance that closely matches theoretical models.

Different sputtering targets and power supplies as well as film thickness monitoring and control device equipped can deposit a variety of film systems, such as metals, oxides, compounds and other high-melting film materials, and also available to coat super-hard films on glass panels.

Automatic substrate loading and unloading as well as automatic process control have reduced the labor cost and human mal-operation, ensuring the superior quality of the high-end coated products, with the production efficiency greatly improved.

Typical application area: various optical films, decorative films and hard films as following:

A), Optical films for mobiles and automobiles (such as various color films, glare gradient color film, AR film, hard film, AFS, etc.);

B), Optical film for imaging equipment (example: PBS, IR-Cut, etc.);

C), Optical communication film (such as NBPF);

D), Optical film for LED (DBR, ODR);

E), Optical film for medical equipments (AR, IR-Cut, HR, etc.);

F), Decorative coating (various colors, RGB, etc.).

(Specially designed for mobile shell coating)

Smart Sputtering-Optical Coater uses MF magnetron sputtering technology to coat a multilayer optical film layers by aid of the activating and cleaning functions of MF or RF plasma device.

More recently, advances in sputtering technology have resulted in coating equipment capable of producing complex optical coatings of more than 200 layers. Advanced plasma reactive sputtering (APRS) uses MF dual-magnetrons and achieves consistent, repeatable rates of deposition with highly predictable thin-film optical characteristics. Armed with accurate optical and time-based layer monitoring techniques, APRS is capable of producing complex filters with spectral performance that closely matches theoretical models.

Different sputtering targets and power supplies as well as film thickness monitoring and control device equipped can deposit a variety of film systems, such as metals, oxides, compounds and other high-melting film materials, and also available to coat super-hard films on glass panels.

Automatic substrate loading and unloading as well as automatic process control have reduced the labor cost and human mal-operation, ensuring the superior quality of the high-end coated products, with the production efficiency greatly improved.

Typical application area: various optical films, decorative films and hard films as following:

A), Optical films for mobiles and automobiles (such as various color films, glare gradient color film, AR film, hard film, AFS, etc.);

B), Optical film for imaging equipment (example: PBS, IR-Cut, etc.);

C), Optical communication film (such as NBPF);

D), Optical film for LED (DBR, ODR);

E), Optical film for medical equipments (AR, IR-Cut, HR, etc.);

F), Decorative coating (various colors, RGB, etc.).

Country of Origin:

China

Product Specification

| Brand Name : | XF |

| Model No : | any |

| Material : | steel |

| Color : | any |

| Size : | any |

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | 13929890xxxxx |

All the pvd metallizers look similar but those made by china pvd metallizer manufacturer co. ltd. are surely different and unique. based on high technology and strict management introduced from south korea and manufactured in china production center. \n\nthe company enjoys good credit, high quality and moderate price in the...

View Profile

Supplier Info:

China Pvd Metallizer Co

China

China

Year Established: 1992

Business Type:

- Manufacturer

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: China Pvd Metallizer Co

More Products From This Supplier

Related Products

- CNC Press Brake

- Hydraulic Griptec Coupler

- Auto Cold Drawing Machine - HS300

- Metal Cutting Machine Tools S-640V

- Automatic Cylinder Honing Machine MVR220

- Collaborative Robots and Robotic Arms

- 3D CNC Wire Bending Machine

- Bluslot Cooling System Circulating Water

- BS-D30 Wire Grinding Machine With 300KG/H

- Brass Inserts

- Automatic Trimming Machine GT-CG30PLC

- Automated guided vehicle -Forklift-Traction-Underpin

.jpg)