SPD-V020 Multifunctional Strand Condition Monitor for Continuous Steel Casting

SPD-V020 Multifunctional Strand Condition Monitor for Continuous Steel Casting

| Country of Origin | China |

| MOQ | 1 Piece |

| Price | USD 10000 / Piece |

| Category | Machinery & Industrial Supplies Metallurgy Machinery & Parts |

Contact SPD-V020 Multifunctional Strand Condition Monitor supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

SPD-V020 Multifunctional Strand Condition Monitor

In the production process of the multifunctional strand condition monitor, in order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range.

Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure.

Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet.

Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline segregation.

The measurement of the strand condition monitor

Roll gap value:

By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed.

It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster.

Outer arc guide roller to arc:

By measuring the deviation between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and the CCM’s original position, we can obtain the arc condition of the outer arc guided roller.

Guided roller rotation:

It is possible to know whether each guided roller can rotate freely by measuring.

Water spray pressure:

The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal.

The main components of the strand condition monitor

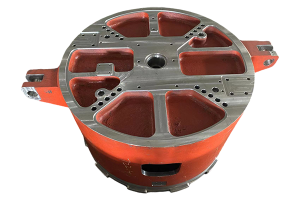

1. The main body of the strand condition monitor used to measure the continuous casting sector

2. The connecting chain between strand condition monitor and dummy bar

3. The storage rack chain of strand condition monitor

4. Battery charger: 24V 5A

5. Calibration equipment

6. Remote control

7. Laptop

8. Printer

9. Data communication cable

The technical parameter

1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements)

2. The measurement accuracy of roll gap: 0.01mm

3. The arc measurement range: ±80

4. The arc measurement accuracy: 0.01°

5. The spray measurement range: 0-10

6. The spray measurement accuracy: ±1

7. The battery usage times: >3 times

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact zero zero eight six one three nine nine five five eight eight five nine seven

| Packaging Info: | carton |

| Delivery Info: | 30 days |

Product Specification

| Model Number : | SPD-V020 |

Product Usages

The SPD-V020 Multi-functional Strand Condition Monitor is designed to be used in the continuous casting process of steel production. It enables users to measure critical parameters and performance indicators of the continuous casting machine (CCM) by simulating the drawing of steel billets.

The monitor allows real-time control and analysis of the CCM's quality, assisting maintenance personnel in identifying potential issues and ensuring optimal product quality.

Product Keywords: continuous casting monitor, steel casting measurement system, strand condition measuring device, CCM performance control, steel billet simulation equipment, roll gap measurement tool

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8613995xxxxx |

Supplier Info:

Wuhan CenterRise M&C Engineering CO. Ltd.

Hubei, China

Hubei, China

Year Established: 2007

Business Type:

- Manufacturer

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Wuhan CenterRise M&C Engineering CO. Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 00 / Kilogram

- MOQ: 5 Kilogram

-

- Price: USD 600 / Tons

- MOQ: 1 Tons

-

- Price: USD 10000 / Pieces

- MOQ: 1 Pieces

- vibrating sand falling machine

- Miniature Linear Guideway LMN series

- Gravity Tool

- Stainless Steel Coil Alloys

- 300KN Steel Bar Tensile Testing Machine

- HMS 1 2 Scrap Used Railway Track Bulk Steel Scrap

- Stainless Steel Pleated Filter Disc

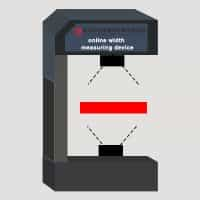

- WGS-L020 Flat Steel/Ribbon Iron Width Measuring System

- Stainless Steel Spring Wires

- Cardan shaft SWC285

- Tooth Point Digging Excavator Bucket Teeth casting

- 304 Solid Core Stainless Steel Ball Bearing Beads