ZSQ-T100 Online Billet Defects Inspection System, Eddy Current, Bulk Price

ZSQ-T100 Online Billet Defects Inspection System, Eddy Current, Bulk Price

| Country of Origin | China |

| MOQ | 1 Piece |

| Price | USD 10000 / Piece |

| Category | Machinery & Industrial Supplies Metallurgy Machinery & Parts |

Contact Online Billet Defetcs Surface Inspection (Eddy Current) supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

ZSQ-T100 Online Billet Defetcs Surface Inspection (Eddy Current)

ZSQ-T100 Online Billet Defects Surface Inspection System (Eddy Current) is a sophisticated solution designed for detecting surface defects in casting billets using eddy current technology.

The principle of the system

The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing.

According to the section of the continuous casting machine and the shape of the casting billet, the eddy current sensors of different structures can be used to realize the non-contact surface defect detection on the surface of the billet, and draws the surface defect graph of the billet in real time according to the detection results.

The composition of the system

Detection frame: The detection frame is used to support the central detection sensor. The height of the detection frame can be adjusted automatically by the motor, so that the central detection sensor is aligned with the casting billet to be inspected.

Front and rear vertical nip roll device: The front and rear vertical nip rolls are used to make the inspected billet pass through the central detection head at an even and stable speed. The pressure roller is double pushed by the cylinder and the spring.

Central testing host: The central testing host is placed on the testing table. It has a four-sided control disc that scans the surface of each casting billet.

Descaling device: It is used to remove the oxide scale on the surface of the casting billet and eliminate the influence of noise on the eddy current flaw detection.

System console: used to control the equipment and the entire testing process, control the mechanical actions of each unit and adjust the instrument parameters. It can realize automatic flaw detection online detection.

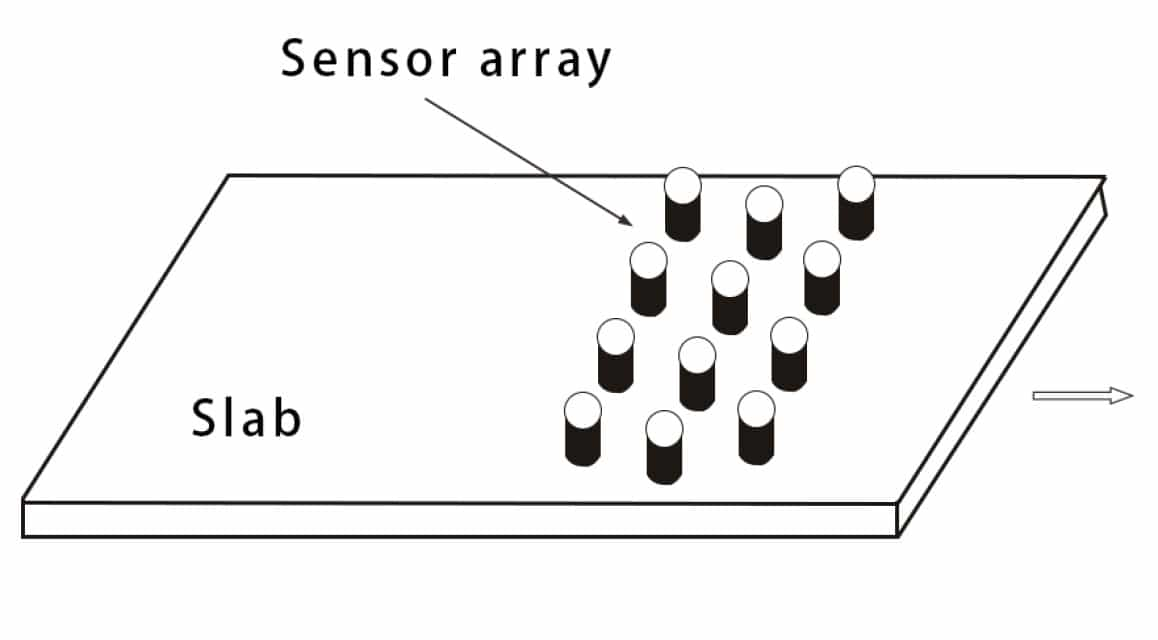

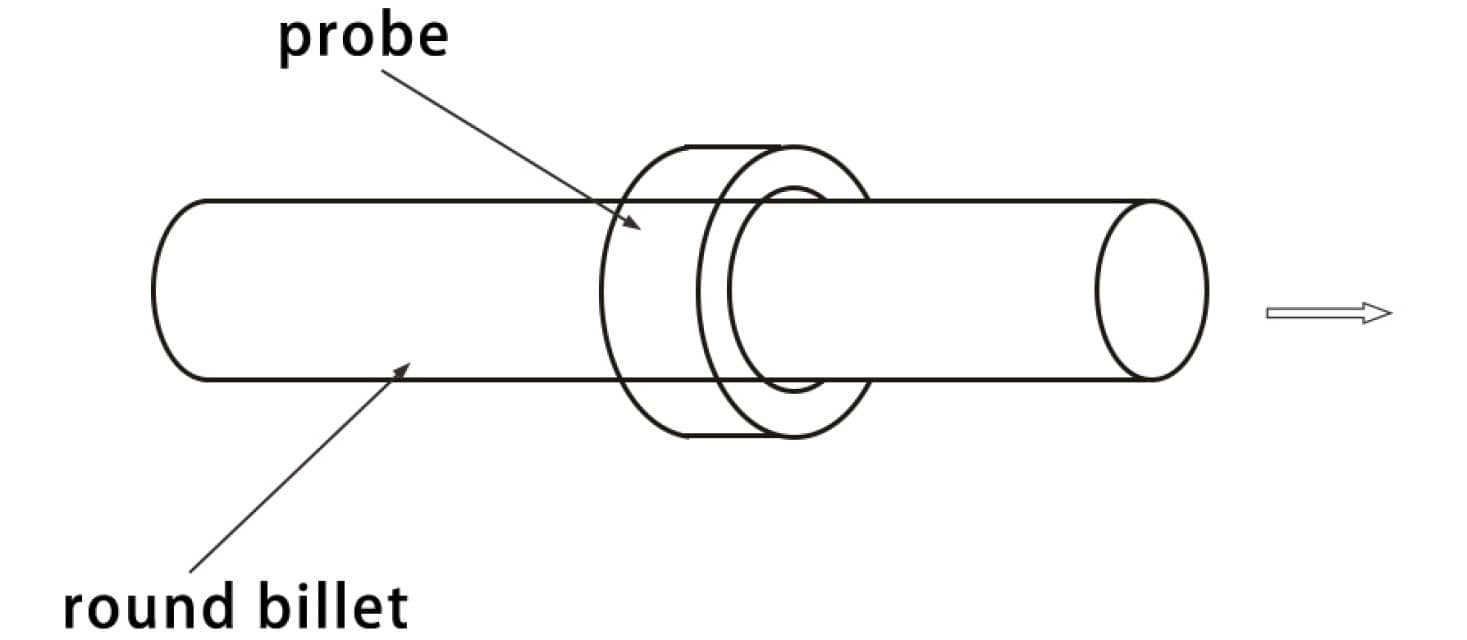

Sensors: Slabs generally use eddy current sensor arrays to test the surface quality of the casting billet. Square billets, round billets and shaped billets generally use through-type eddy current probes to test the surface quality of the casting billets.

The main technical index of the eddy current testing on the surface of continuous casting billets

1. The objects of flaw detection: slabs, round billets, square billets and shaped billets of various sizes.

2. The steel grade of the casting billet: ordinary low-carbon steel or alloy steel.

3. Detection temperature: 400~1000℃.

4. Detection speed: ≤3~40m/min.

5. Allowable speed fluctuation range: 0~40m/min.

6. Detection of defect types and sizes: scratches with a depth or height greater than 1.5mm, wrinkled skin lines, cold splashes, bumps, pits and longitudinal facial cracks, transverse cracks, mesh cracks, and subsurface inclusions with a depth greater than 3mm.

7. Blind spot for flaw detection at the end of the casting billet: 25mm.

8. Detection frame area: ≤3m (transmission line direction)

The ZSQ-T100 supports a broad temperature range from 400°C to 1000°C and accommodates detection speeds of up to 40 meters per minute. It efficiently detects defects with a depth or height greater than 1.5mm and is suitable for various steel grades, including low-carbon and alloy steel.

| Packaging Info: | carton |

| Delivery Info: | 30 days |

Product Specification

| Model Number : | ZSQ-T100 |

Product Usages

The ZSQ-T100 Online Billet Defects Surface Inspection System is designed for continuous, non-destructive testing of casting billets. It is used to detect surface defects such as scratches, cracks, and pits on billets of different shapes and sizes.

The system operates by passing billets through a central sensor that scans for imperfections. It is essential for ensuring the quality and integrity of billets in metallurgy processes.

The system requires minimal maintenance and is easy to operate, with automated controls for adjusting parameters and managing the inspection process.

Product Keywords: Square billet detection devices, square billet detection instruments, steel surface inspection system, billet surface defect detection system, eddy current billet inspection, ZSQ-T100 billet inspection price, wholesale billet inspection system, China billet defect detection equipment, bulk eddy current testing system, billet inspection supplier China, ZSQ-T100 inspection system rate

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8613995xxxxx |

Supplier Info:

Wuhan CenterRise M&C Engineering CO. Ltd.

Hubei, China

Hubei, China

Year Established: 2007

Business Type:

- Manufacturer

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Wuhan CenterRise M&C Engineering CO. Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 00 / Kilogram

- MOQ: 5 Kilogram

-

- Price: USD 0 / Kilogram

- MOQ: 10000 Kilogram

- sand preparation system

- HMS 1 2 Scrap Used Railway Track Bulk Steel Scrap

- 3000kN Concrete Cube Compression Testing Machine

- LDC-X200 Laser Diameter Measuring System

- Supply Case 5174044 85257511 BT8899 SPH9914 Filter

- CNC Centerless Grinding Machine

- Composite Bonding Autoclave

- Linking stem valve

- EATON AIRFLEX 20CB500 142265KM

- All kinds of high-quality muffle furnace

- Cone Crusher Eccentric Sleeve

- CAMERON interchangeable wafer butterfly valve