AISI 4340 Steel Round Bar - High Strength and Toughness

AISI 4340 Steel Round Bar - High Strength and Toughness

| Country of Origin | China |

| MOQ | 1 Tons |

| Price | USD 888 / Tons |

| Category | Minerals & Raw Materials Alloy |

Contact AISI 4340 Steel Round Bar - High Toughness AISI 4340 Steel Round Bar supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

AISI 4340 Steel Round Bar | High Toughness AISI 4340 Steel Round Bar

AISI 4340 Steel Round Bar is a high-strength alloy offered by Dongguan Songshun Mould Steel Co. Ltd. This versatile product is perfect for manufacturing large and medium-sized plastic molds requiring exceptional strength and toughness.

It also excels in producing quality controlling parts with outstanding toughness, high strength, and ample size, making it ideal for heavy machinery.

It is an alloy structural grade which used by the SAE International(SAE), and it is chrome-nickel low alloy steel. 4340 steel round bar sheet plate will get high tensile strength, hardness and toughness after heat treatment.

It is used widely in the transmission components of heavy chemical machinery.

Different sections of each part of the casting which cause the temperature difference stress and phase transformation stress. If you can’t get their laws and characteristics, you can’t take the right rational processes.

The consequence is that there is a risk of cracking the casting during the casting or heat treatment. So the control of chemical composition and the choice of the heat treatment process for the casting are really important.

- 4340 Steel Mechanical Properties

- Properties Metric Imperial

- Tensile strength >980 MPa 142140 psi

- Yield strength >835 MPa 121110 psi

- Elongation at break >12% >12%

- Reduction of area >55% >55%

- Hardness ≤269HB ≤269HB

1.6511 Steel Characteristics

1.It has great atmospheric corrosion resistance, fatigue resistance and strength.

2.Stay excellent toughness, wear resistance and fatigue strength after heat treated.

3.It is alloy steel with low carbon and high nickel. About the coating and softening for leather knife sheath, it is a great choice.

4.4340 alloy steel bar is used widely in the aerospace industry because of great strength.

4340 Steel Round Bar Sheet Plate Heat Treatment and Process

Stress Relieving

For pre-hardened steel stress relieving is achieved by heating steel 4340 to between 500 to 550°C. Heat to 600 °C – 650 °C, hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm section, and cool in still air.

Cold Working

AISI 4340 alloy steel can be cold worked using all conventional methods in the annealed condition. It has high ductility.

Annealing

A full anneal may be done at 844°C (1550 F) followed by controlled (furnace) cooling at a rate not faster than 10°C (50 F) per hour down to 315°C (600 F). From 315°C 600 F, it may be air cooled.

Tempering

AISI 4340 alloy steel should be in the heat treated or normalized and heat treated condition before tempering. The tempering temperature for depends upon the strength level desired. For strength levels in the 260 – 280 ksi range temper at 232°C (450 F). For strength in the 125 – 200 ksi range temper at 510°C (950 F).

And don’t temper the 4340 steels if it is in the 220 – 260 ksi strength range as tempering can result in degradation of impact resistance for this level of strength. Tempering should be avoided if possible within the range 250 °C – 450 °C due to temper brittleness.

4340 Steel Heat Treatment

AISI 4340 alloy steel is heat treated at 830°C (1525°F) followed by quenching in oil.

Flame or Induction Hardening

As mentioned above, pre-hardened and tempered 4340 steel bars or plates can be further surface hardened by either the flame or induction hardening methods resulting in a case hardness in excess of Rc 50.

AISI 4340 steel parts should be heated as quickly as possible to the austenitic temperature range (830 °C – 860 °C) and required case depth followed by an immediate oil or water quenching, depending upon hardness required, workpiece size/shape and quenching arrangements.

Following quenching to hand warm, tempering at 150°C – 200°C will reduce stresses in the case with minimal effect on its hardness.

All de-carburized surface material must first be removed to ensure the best results.

Nitriding

Hardened and tempered 4340 alloy steel can also be nitrided, giving a surface hardness of up to Rc 60. Heat to 500°C – 530°C and hold for sufficient time (from 10 to 60 hours) to develop the depth of the case. Nitriding should be followed by slow cooling (no quench) reducing the problem of distortion.

The nitrided grade 4340 materials can therefore be machined to near final size, leaving a small grinding allowance only. The tensile strength of the 4340 steel material core is usually not affected since the nitriding temperature range is generally below the original tempering temperature employed.

Surface hardness achievable is 600 to 650HV.

Machinability

It can be machined using all conventional techniques. Machining process can be performed in the annealed or normalized and tempered conditions.

Welding

Welding of steel in the hardened and tempered condition (as normally supplied), is not recommended and should be avoided if at all possible, because of the danger of quench cracking, as the mechanical properties will be altered within the weld heat affected zone.

If welding must be carried out, pre-heat to 200 to 300°C and maintain this while welding. Immediately after welding stress relieve at 550 to 650°C, prior to hardening and tempering.

If welding in the hardened and tempered condition is really necessary, then the work piece, immediately on cooling to hand warm, should be if possible stress relieved at 15 °C below the original tempering temperature.

We are a professional special steel stockist and supplier with a high-quality stand for many years. As a professional 4340 steel supplier, we can supply 4340 steel for your different applications as above. If you need technical guide, we also can be your strong support, please contacts us for any request for it. Songshun Steel always with you.

By the way, 4140 steel has similar properties and its cost is lower than 4340 steel. Just go to visit 4140 steel application and properties.

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union...... |

| Packaging Info: | 1. Standard export package 2. In bundles with steel strips 3. Meet requirements of customers |

| Delivery Info: | 7-25 days |

Product Specification

| Model Number : | 4340/40CrNiMoA/G43400/36CrNiM |

| Color : | Can be negotiate |

| Size : | Can be negotiate |

| Weight : | Can be negotiate |

| Style : | 4340 Steel Round Bar |

| Technology : | Hot Rolled/Forged |

| Standard : | AISI/ASTM/DIN/NF/JIS/GB/BS |

| Grade : | AISI 4340/GB 40CrNiMoA/UNS G43400/DIN 36CrNiMo4 |

| Brand Name : | SONGSHUN |

Product Usages

AISI 4340 Steel Round Bar is your go-to solution for applications that demand strength and toughness. This versatile alloy steel is perfect for manufacturing large and medium-sized plastic molds requiring exceptional resilience.

It excels in quality controlling parts, offering outstanding toughness, high strength, and reliability. Used in heavy machinery and transmission components, it thrives in conditions with temperature difference stress and phase transformation stress.

By controlling chemical composition and implementing precise heat treatment, you can ensure its longevity and performance. Trust AISI 4340 Steel Round Bar for your critical applications.

Product Keywords: High Toughness Alloy Steel, AISI 4340 Steel Manufacturer, Heavy Machinery Components, Nickel-Chromium-Molybdenum Alloy, Quality Controlling Parts, 4340 Steel Round Bar Supplier

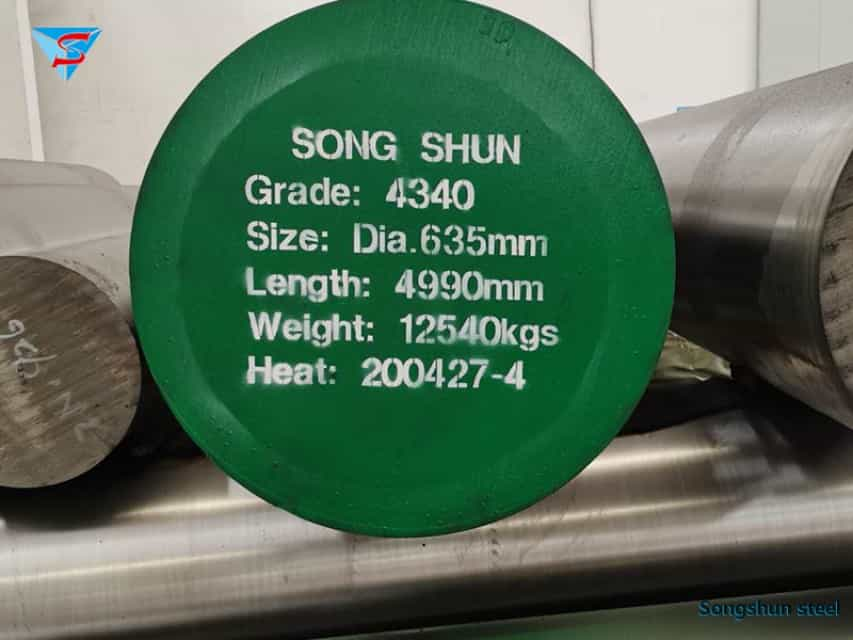

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8618269xxxxx |

Supplier Info:

Dongguan Songshun Mould Steel Co. Ltd.

Guangdong, China

Guangdong, China

Year Established: 2009

Business Type:

- Manufacturer

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Dongguan Songshun Mould Steel Co. Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 30 / Kilogram

- MOQ: 400 Kilogram

-

- Price: USD 22000 / Tons

- MOQ: 1 Tons

-

- Price: USD 5600 / Tons

- MOQ: 3 Tons

- Aluminium Alloy Wheel Scrap

- Manganese Metal Lumps/Briquettes/Flakes/Powder

- GR5 Titanium Bars Dia 60MM

- 430 stainless steel strips

- AISI 4140 Steel Round Bar Sheet Plate, JIS SCM440, DIN 1.7225

- DC/Cc Aluminium Round Circle Mill Finish

- Alloy 20 Round Bar

- 201 Cold Rolled Stainless Steel Coil

- Heat Treating Steel

- ASTM 12M steel PIPE ON SALE 316L stainless steel tube

- Cr12MoV Steel Speacial Tool steel

- Aluminium Bronze Bar