1.3343 Steel Material | DIN 1.3343 Steel Material Fabrication

1.3343 Steel Material | DIN 1.3343 Steel Material Fabrication

| Country of Origin | China |

| MOQ | 1 Tons |

| Price | USD 1200 / Tons |

| Category | Minerals & Raw Materials Iron & Steel Copper |

Contact supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

1.3343 Steel Material | DIN 1.3343 Steel Material Fabrication

M2 Steel Mechanical Properties

Mechanical properties Metric Imperial

Hardness, Rockwell C(tempered at 1150°F, quenched at 2200°F) 62 62

Hardness, Rockwell C(as hardened, quenched at 2200°F) 65 65

Compressive yield strength(when tempered at 300°F) 3250 MPa 471000 psi

Izod impact unnotched(when tempered at 300°F) 67 J 49.4 ft-lb

Abrasion(loss in mm3, as-hardened; ASTM G65) 25.8 25.8

Abrasion(loss in mm3, tempered at 1275°F; ASTM G65) 77.7 77.7

Poisson’s ratio 0.27-0.30 0.27-0.30

Elastic modulus 190-210 GPa 27557-30458 ksi

M2 Steel Round Bar Sheet Plate Heat Treatment

Machinability

The shaping of M2 tool steels may be executed using grinding strategies. But, which has bad grinding capability. So they’re called as “medium” machinability tool steel under annealed conditions. The machinability of these steels is only 50% of that of the easily machinable W group or water hardening tool steels.

Annealing

Heat to 1600° F, soak thoroughly at heat. Furnace cool 25° F per hour to 900° F, air cool to room temperature. Approximate annealed hardness 241 Maximum Brinell.

Stress Relief of Unhardened Material: Heat slowly to 1200 to 1250° F. Soak for two hours per inch of thickness at heat. Slow cool(furnace cool if possible) to room temperature.

Hardening

Heat M2 steel slowly to 1550° F, soak fully, heat to 1850° F, soak thoroughly. Soak time in the furnace varies from a few minutes to 15 minutes, depending on tool size, the heat capacity of the furnace, and the size of the charge. – Heat to 2150 to 2200° F for max. toughness and minimum distortion. – Heat to 2250 to 2275° F for max.

Tempering

Double tempering is necessary, sometimes preferred three times tempering. Soak for 2 hours per inch of thickness. Air cool to room temperature between tempers. The best tempering range for hardness, strength and toughness is 1000 to 1050° F.

Quenching

For full hardness, need to oil quench to 150-200° F. Air quenches to 150° F. When quenching in hot salt maintains the quench just above the Ms temperature. After equalizing withdraw parts from the hot salt and air cooled to 150° F.

M2 high speed steel is preheated prior to hardening at 2610 ° C(4730 ° F). Then heated rapidly from 2610 ° C (4730 ° F) to 3960 ° C (7160 ° F). The steel is finally cooled for 3 to 5 minutes and quenched in air, salt bath or oil.

M2 Steel Quality Certificate Certificate & SGS Report

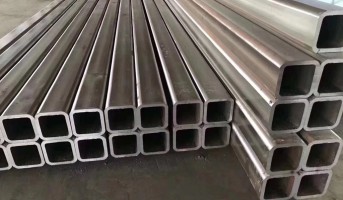

M2 Tool Steel Round Bar Sheet Plate Supply

Round Bar

Specification: Dia 12-220mm; Length: Can be customized

Surface: Black Surface/Bright Surface /Grinded/Peeled/Turned

Sheet/Plate/Slab

Specification: thickness: 3-200mm; width: Can be customized; length: Can be customized

Surface: Black Surface/Bright Surface /Grinded/Peeled/Turned

Notice

We have our own cutting and processing equipment. Specifications can be cut and customized according to your requirements.

We are a professional special steel stockist and supplier with a high-quality stand for many years. As a professional M2 steel supplier, please contacts us for any request of AISI M2/DIN 1.3343 steels materials. Songshun Steel always with you.

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union...... |

| Packaging Info: | Packaging according to customer requirements |

| Delivery Info: | 7-25 days |

Product Specification

| Model Number : | 1.3343 W6Mo5Cr4V2 SKH51 M2 |

| Color : | Negotiable |

| Size : | Negotiable |

| Weight : | Negotiable |

| Style : | Hight Speed Steel Bar |

| Technology : | Hot Rolled/Forged/Cold drawn |

| Standard : | AISI/ASTM/DIN/NF/JIS/GB/BS |

| Grade : | 1.3343 Steel |

| Brand Name : | Songshun |

| Tolerance : | ±10% |

| Processing Service : | Bending, Decoiling, Cutting, Punching |

Product Usages

The application is decided by M2 steel chemical composition and properties. It has high hardness, red hardness. Good thermoplasticity and excellent toughness. It is used to make tools that require has good wear resistance and toughness which can sustain l

Product Keywords: 1.3343 Steel Material

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8618269xxxxx |

Supplier Info:

Dongguan Songshun Mould Steel Co. Ltd.

Guangdong, China

Guangdong, China

Year Established: 2009

Business Type:

- Manufacturer

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Dongguan Songshun Mould Steel Co. Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 1000 / Kilogram

- MOQ: 100 Kilogram

-

- Price: USD 8500 / Tons

- MOQ: 3 Tons

- Indolift Alloy Steel Chain

- Duplex Stainless Steel Sheet & Plate

- M35 High-Speed Steel Round Bar Sheet Plate

- API 5L X42 Steel Pipe

- Stainless Steel Scrap

- SSAW Steel Pipe

- Duplex Steel Pipe Fitting

- 7/16" 1X7 EHS Galvanized Guy Strand Cable

- Prepainted Galvanized Steel Coil Ppgi Aluminium Steel Coil

- Steel plate factory | Low Cost hot rolled steel plate factory

- High Quality ASTM Steel Rod 410 420 416 Stainless Steel Round Bar

- Cheap factory price metal iron cold rolled coil steel strip