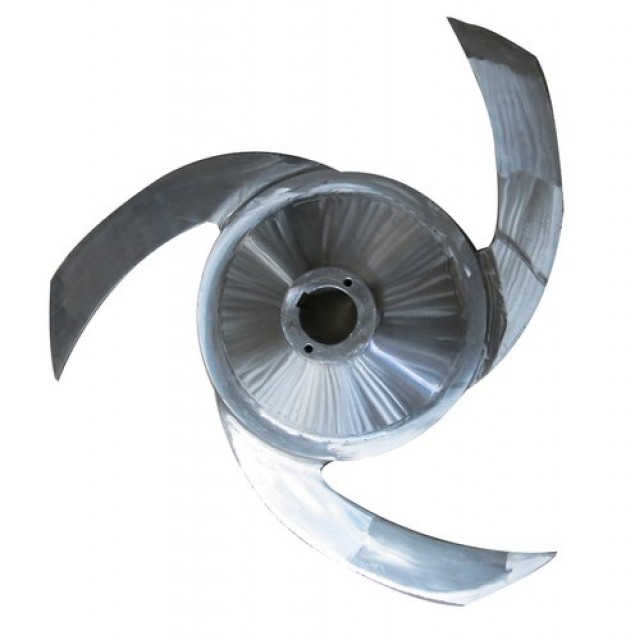

Impeller - For Pulp & Paper Mill

Impeller - For Pulp & Paper Mill

USD 1 / Piece

| Country of Origin | India |

| MOQ | 1 Piece |

| Price | USD 1 / Piece |

| Category | Machinery & Industrial Supplies Metallurgy Machinery & Parts |

Contact supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

Impeller - For Pulp & Paper Mill

Application & Salient Feature

Hi-Consistency pulper is connected with dilution pulper. The dilution pulper has a due function of separating the plastics and other foreign material as also dilute the high consistency for stock transfer for further processing. This pulp has 0 6-8 mm drilled screen plate with the impeller rotating against the screen. The impact of impeller separates the fiber from the rejects, hence working most efficiently for fiber recovery.

The Advantages Are

Uncut contaminates from Hi-consistency pulper are removed with negligible fiber loss.

The hi-consistency pulper is ready for next batch immediately after emptying out. The isolating valve isolates Dilution pulper from the main pulper.

The dilution pulper works as first coarse screen thus reducing a load on next stage equipment.

Removal of large foreign contaminants eliminates the risk of pulp jamming in successive operation.

Hi-Consistency pulper is connected with dilution pulper. The dilution pulper has a due function of separating the plastics and other foreign material as also dilute the high consistency for stock transfer for further processing. This pulp has 0 6-8 mm drilled screen plate with the impeller rotating against the screen. The impact of impeller separates the fiber from the rejects, hence working most efficiently for fiber recovery.

The Advantages Are

Uncut contaminates from Hi-consistency pulper are removed with negligible fiber loss.

The hi-consistency pulper is ready for next batch immediately after emptying out. The isolating valve isolates Dilution pulper from the main pulper.

The dilution pulper works as first coarse screen thus reducing a load on next stage equipment.

Removal of large foreign contaminants eliminates the risk of pulp jamming in successive operation.

Country of Origin:

India

| Payment Terms: | L/C (Letter of Credit),T/T (Bank Transfer) |

| Delivery Info: | Immediate |

Product Specification

| Brand Name : | Parason |

| Material : | Stainless Steel |

| Automation Grade : | Automatic |

| Usage/Application : | Industrial |

| Suitable for : | Custom |

| Impeller Diameter : | Variable |

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +9109607xxxxx |

Parason Group is one of the largest manufacturer & Supplier of pulp and paper machinery. Renowned scientist & metallurgist Dr. Desarda is Founder & Chairman of the Company. Parason started its first research unit for pulp and paper machinery in the Year 1977. Parason is focused on Research & Development....

View Profile

Supplier Info:

Parason Machinery India Pvt Ltd

Maharashtra, India

Maharashtra, India

Year Established: 1977

Business Type:

- Exporter

- Trading

- Manufacturer

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Parason Machinery India Pvt Ltd

More Products From This Supplier

Related Products

- Shenghui Electric Gear Oil Transfer Pump

- Elliptical Head

- Surface Finish-Precision Aluminum Parts

- Seamless Hot Rolled Steel Pipe Perforating Machinery

- Double Hexagon Shape Rebar Coupler

- Chains for Bagasse Carrier

- Horizontal Honing Machine MRL1805

- Threaded Rod

- Cardan shaft for steel rolling mill

- slag pot for steel mill

- Refiner Plates - For Pulp & Paper Mills

- Rigid impeller feeder