Screen Plate - For Pulp and Paper Mill

Screen Plate - For Pulp and Paper Mill

USD 1 / Piece

| Country of Origin | India |

| MOQ | 1 Piece |

| Price | USD 1 / Piece |

| Category | Machinery & Industrial Supplies Metallurgy Machinery & Parts |

Contact supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

Screen Plate - For Pulp and Paper Mill

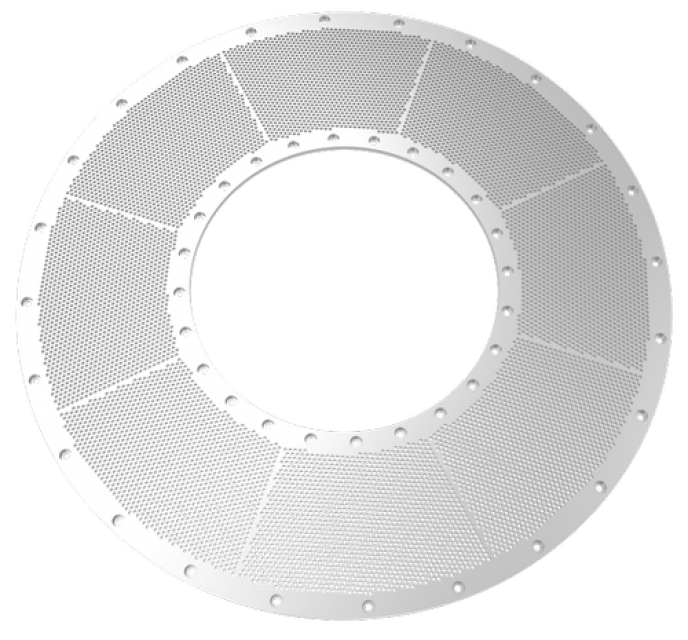

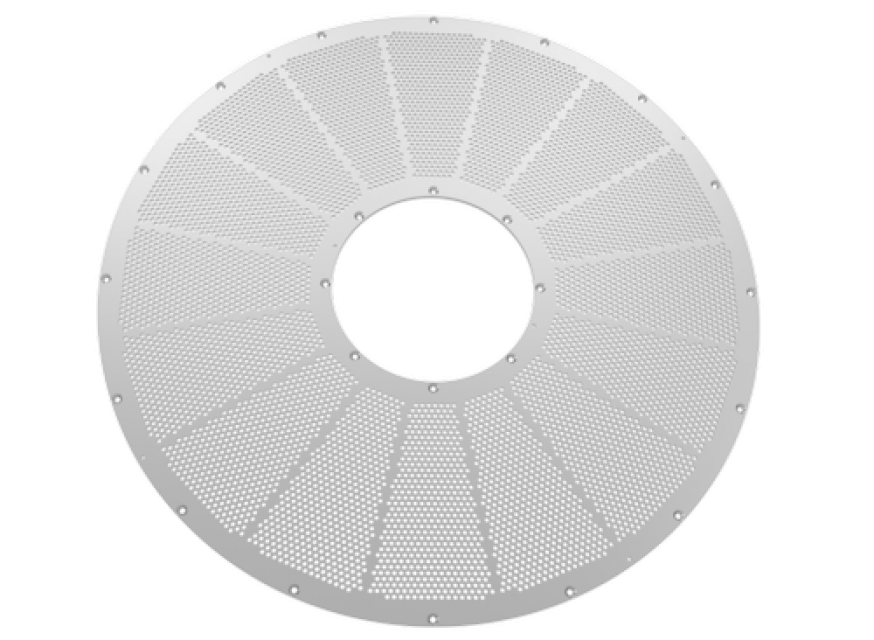

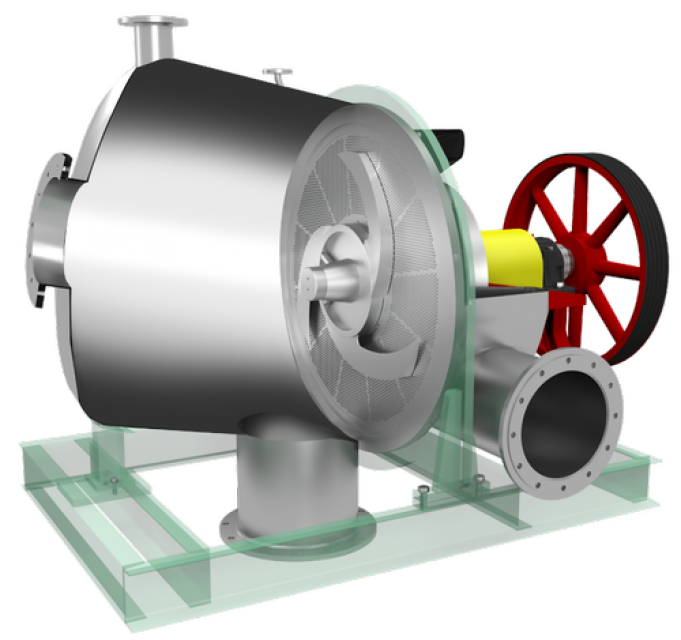

Screen plate is used in the screen basket. Screening equipment is an important operational system for pulp processing. Screen plate is situated in pulper. The stator and rotor are placed on the screen plate. Pulper has a rotor inside the machine that grinds and mixes the pulp evenly.

The pulp is made of fiber material obtained from trees and other waste material like office paper, newspaper, vegetable fiber, etc. all the fiber is taken to the pulper machine and is cut down into small pieces and mixed with water. The waste fiber contains contaminants, also the uncut fiber is separated with the help of the screen plate.

Contaminants may damage the product as well as the machine. It is necessary to separate the contaminants from pulp to get efficient results.

Screen plate work as a strainer that separates large, uncut particles from pulp to separate and collect them to other containers. The pulp is passed through the strainer for further procedure. Contaminants stay collected on screen plate and don’t mix with the pulp. Screen plate works continuously into the water. Therefore, it has to be made by corrosion resistance material.

The pulp is the main constituent of manufacturing paper, which collects the cellulose fiber from fiber material. Everyday use of paper has increased as the paper is easy to dispose of and does not harm the environment. The pulp is manufactured in tons every day, as the paper pulp is used to make paper bags, paper products, etc. As there is growth in the use of paper, paper industries are also growing.

Paper industries used fiber material to manufacture pulp such as wood fiber is the main constituent of manufacturing paper. As the increase in global warming, cutting down trees are not possible, that can affect the environment. Waste fiber can be used to make paper pulp, where they can also give the same result as that of the wood fiber.

Parason screen plate is made of stainless steel as it has to work continuously in water. Screen plate is easy in installation and has a long life. Screen plate works efficiently into pulper and separates the contaminants from the pulp.

The pulp is made of fiber material obtained from trees and other waste material like office paper, newspaper, vegetable fiber, etc. all the fiber is taken to the pulper machine and is cut down into small pieces and mixed with water. The waste fiber contains contaminants, also the uncut fiber is separated with the help of the screen plate.

Contaminants may damage the product as well as the machine. It is necessary to separate the contaminants from pulp to get efficient results.

Screen plate work as a strainer that separates large, uncut particles from pulp to separate and collect them to other containers. The pulp is passed through the strainer for further procedure. Contaminants stay collected on screen plate and don’t mix with the pulp. Screen plate works continuously into the water. Therefore, it has to be made by corrosion resistance material.

The pulp is the main constituent of manufacturing paper, which collects the cellulose fiber from fiber material. Everyday use of paper has increased as the paper is easy to dispose of and does not harm the environment. The pulp is manufactured in tons every day, as the paper pulp is used to make paper bags, paper products, etc. As there is growth in the use of paper, paper industries are also growing.

Paper industries used fiber material to manufacture pulp such as wood fiber is the main constituent of manufacturing paper. As the increase in global warming, cutting down trees are not possible, that can affect the environment. Waste fiber can be used to make paper pulp, where they can also give the same result as that of the wood fiber.

Parason screen plate is made of stainless steel as it has to work continuously in water. Screen plate is easy in installation and has a long life. Screen plate works efficiently into pulper and separates the contaminants from the pulp.

Country of Origin:

India

| Payment Terms: | L/C (Letter of Credit),T/T (Bank Transfer) |

| Delivery Info: | Immediate |

Product Specification

| Brand Name : | Parason |

| Material : | Stainless Steel |

| Size : | Variable |

| Automation Grade : | Automatic |

| Brand : | Parason |

| Capacity : | Custom |

| Size/Dimension : | Variable |

| Usage/Application : | Industrial |

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +9109607xxxxx |

Parason Group is one of the largest manufacturer & Supplier of pulp and paper machinery. Renowned scientist & metallurgist Dr. Desarda is Founder & Chairman of the Company. Parason started its first research unit for pulp and paper machinery in the Year 1977. Parason is focused on Research & Development....

View Profile

Supplier Info:

Parason Machinery India Pvt Ltd

Maharashtra, India

Maharashtra, India

Year Established: 1977

Business Type:

- Exporter

- Trading

- Manufacturer

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Parason Machinery India Pvt Ltd

More Products From This Supplier

Related Products

-

- Price: USD 00 / Kilogram

- MOQ: 5 Kilogram

- CNC Gear Measuring Machine Econ 30

- API 5L X52 steel pipe

- High-Temperature Bearing

- Titanium Products

- Brass Lock Nut

- fertilizer blending equipment

- plate shot blasting machine

- Roller Standard LMR Series

- Gravity Tool

- NDW Computer Screen Control Steel Torsion Testing Machine

- SPD-V010 Handheld Roll Gap Checker

- Cardan shaft for steel rolling mill