MIL-STD-810H Dual Blowing Dust Sand Test Machine - Robust Defense Testing Equipment

MIL-STD-810H Dual Blowing Dust Sand Test Machine - Robust Defense Testing Equipment

| Country of Origin | China |

| MOQ | 1 Sets |

| Price | USD 200000 / Sets |

| HS Code | EVCL-216-DS |

| Category | Machinery & Industrial Supplies Electronic Manufacturing Machinery |

Contact MIL-STD-810H Dual Blowing Dust Sand Test Machine supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

enviClone Customized MIL-STD-810H Dual Blowing Dust Sand Test Machine

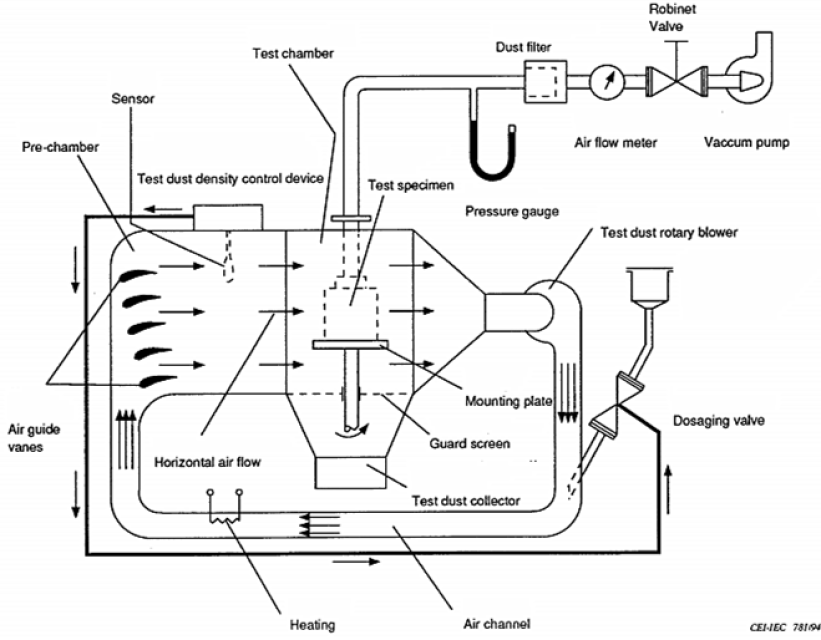

Enviclone Dual Blowing Dust and Sand Test Chamber (Machine) is designed as per MIL-STD-810G now updated into MIL-STD-810H test standard. It is to test the dust proof performance of enclosures of products under the US military defense standard.

Engineering Team of enviClone can design and manufacture this Blowing Dust Sand Chamber with experience of their career. The dimensions of test space can be customized according to your test specimen.

Specification

1. Size of Blown Dust and Sand Test Chamber

Model Volume Internal Dimension External Dimension Power

D*W*H (mm) D*W*H (mm)

EVCL-216-DS 216L 600 x 600 x 700 2000 x 4200 x 2200 45kW

2. Specification

3. Performance Temperature Range 23°C~70°C

Temperature Deviation ≤ ±2°C

Humidity < 30%R.H

Air Velocity 1.5 ~ 8.9 m/s (blown dust)

18.0 ~ 29.0 m/s (blown sand)

Concentration 3.0 ~ 17.6 g/m3 (10.7 ± 7 g/m3) – Blowing dust

0.18 + 0.2 g/m3 -Blowing sand.

1.1 ± 0.3 g/m3 2.2 ± 0.5 g/m3 -Blowing sand

4. Structure External Casing Cold-rolled A3 (Q235) steel plates with plastics painted.

Interior Working Room Stainless Steel Plates SUS304

Air Circulation Multiple-blades anti-abrasive blower

Dehumidification system 0.7 Mpa air pressure, flow volume 10m3/h

Rotation Table RMP and height is adjustable.

Viewing Window 300 x 300 mm big viewing vision

Door Manually operated sliding door with unlock button.

5. Control System Controller Programmable Touch-screen controller with data logging and download function.

Water Storage Failure recording and self-analysis

6. Safety Protection Power leakage protection, over-load or over-current protection/Dry burning protection.

7. Voltage AC220V/380V/440V±10%, 50Hz/60Hz, etc.

Features

1. Strong Structure: Interior part is made of quality stainless steel (SUS#304).

2. Exterior structure is made of solid baked painted steel plate, well anti-rust.

3. Comes with high temperature protection material.

4. Designed with ant-static protection.

5. Controller: programmable, touchscreen, easy to set test values. To control and display Temperature, Humidity, Wind

Speed, Dust Concentration, Test Time, etc.

6. It displays Set Value and Actual Values of Temperature, Relative Humidity, Wind Speed and Dust Concentration as well as the set operation times. Can be manually set.

7. Test data can be downloaded via USB and Lan port.

8. Lower noise design

9. Lower power consumption

10. Interior lights with long lifetime

11. Multiple protections on phase sequence, power leakage, etc.

12. UL certified cables can be used for the United States market.

Test Standard

MIL-STD-810H Method 510.5 Sand and Dust.

Dust (< 150µm) procedure.

Sand (150 to 850µm particle size) procedure.

This method includes two test procedures, Procedure I – Blowing Dust, and Procedure II – Blowing Sand.

The requirement of temperature, relative humidity, air velocity and dust or sand concentration is determined by this test standard.

TEST PROCEDURE 1 – Blowing Dust Test

Step 1. With the test item in the chamber and stabilized at standard ambient temperature, adjust the air velocity to8.9 + 1.3 m/s (1750 + 250 ft/min), or as otherwise determined from the test plan.

Step 2. Adjust the dust feed control for a dust concentration of 10.6 ± 7 g/m3 (0.3 + 0.2 g/ft3).

Step 3. Unless otherwise specified, maintain the conditions of Steps 1 and 2 for at least 6 hours. If required, periodically reorient the test item to expose other vulnerable faces to the dust stream.

Step 4. Stop the dust feed. (See paragraph 4.1.1.7.) Reduce the test section air velocity to approximately 1.5 +1 m/s (300 + 200 ft/min) and adjust the temperature to the required high operational temperature (see paragraph 4.1.1.1), or as otherwise determined from the test plan.

Step 5. Maintain the Step 4 conditions for a minimum of 1 hour following test item temperature stabilization.

Step 6. Adjust the air velocity to that used in Step 1 and restart the dust feed to maintain the dust concentration.

Step 7. Continue the exposure for at least 6 hours or as otherwise specified. If required, operate the test item in accordance with the test plan. If the test item fails to operate as intended, follow the guidance in paragraph 4.2.3.3.2. Otherwise proceed to Step 8.

Step 8. Stop the dust feed and allow the test item to return to standard ambient conditions at a rate not to exceed 3°C/min (5°F/min). Stop any air flow and allow the dust to settle (possibly up to 12 hours).

Step 9. Remove accumulated dust from the test item by brushing, wiping, or shaking, taking care to avoid introduction of additional dust or disturbing any that may have already entered the test item. Do NOT remove dust by either air blast or vacuum cleaning unless these methods are likely to be used in service.

Step 10. Perform an operational check in accordance with the approved test plan and document the results for comparison with pretest data. See paragraph 5.1 for analysis of results.

Step 11. Inspect the test item for dust penetration, giving special attention to bearings, grease seals, lubricants, filters, ventilation points, etc. Then document the results.

TEST PROCEDURE II – Blowing Sand Test

Step 1. Increase the temperature inside this dual blowing sand dust test chamber (at a rate not to exceed 3°C/min (5°F/min) and stabilize the test item at its high operating temperature.

Step 2. Adjust the air velocity according to test plan (see paragraph 4.2.1.2).

Step 3. Adjust the sand feeder to obtain the sand mass flow rate determined from the pretest calibration.

Step 4. Maintain the conditions of Steps 1 through 3 for the duration specified in the test plan. If required, re-orient the test item at 90-minute intervals to expose all vulnerable faces to blowing sand, and repeat Steps 1-step 3.

Step 5. If operation of the test item during the test is required, perform an operational test during the last hour of the test, and document the results. If the test item fails to operate as intended, follow the guidance in paragraph 4.2.3.3. Otherwise proceed to Step 6.

Step 6. Stop the sand feed. Allow the test item to return to standard ambient conditions at a rate not to exceed 3°C/min (5°F/min). Stop any air flow and allow the sand to settle. Remove accumulated sand from the test item by using the methods anticipated to be used in service such as brushing, wiping, shaking, etc., taking care to avoid introduction of additional sand into the test item.

Step 7. Conduct an operational check of the test item in accordance with the approved test plan, and record results for comparison with pretest data. See paragraph 5.2 for analysis of results.

Step 8. Visually inspect the test item looking for abrasion and clogging effects, and any evidence of sand penetration.

About enviClone: Wuxi Enviclone Test Equipment Co., Ltd specializes in environmental simulation and test chambers including temperature humidity chambers, ozone aging chambers, UV aging chambers, salt spray chambers, rain fall waterproof chambers, dual blowing dust sand proof testing machines, dynamic mechanical load testing equipment, walk in climatic chambers, solar raddiation testing chambers, altitude test chambers, and so on for various industries such as automotives, photovoltaic (PV) modules, solar power panels, new energy batteries, rubber manufacturing, electronics, military, etc.

| Payment Terms: | 50%TT with purchasing order and 45%TT before shipping and 5%TT after installation |

Product Usages

Experience efficient and precise dust and sand resistance testing with the MIL-STD-810H Dual Blowing Dust Sand Test Machine. Utilize its programmable touchscreen controller to set and monitor test parameters easily.

The chamber's strong structure, advanced safety features, and customizable dimensions make it an ideal choice for evaluating the dust-proof performance of various product enclosures.

Product Keywords: MIL-STD-810H Dust Test Equipment, Dual Blowing Sand Chamber, Defense Testing Machine, Dust and Sand Resistance Tester, Enviclone Blowing Dust Test Machine, MIL-STD-810H Compliance

Product Images

Supplier Info

| Company Name | : |

|

| Business Type | : |

|

| Supplier Phone: | : | +8618132xxxxx |

Supplier Info:

Wuxi Enviclone Test Equipment Co. Ltd.

Jiangsu, China

Jiangsu, China

Year Established: 2008

Business Type:

- Manufacturer

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Wuxi Enviclone Test Equipment Co. Ltd.

Related Products

-

- Price: USD 3780 / Units

- MOQ: 1 Units

- TG Multi-Arc Ion-Tableware and Kitchenware PVD Coating Machine

- GT-DTF01/03 Cartridge Heater MGO Filling Machine

- ABB Industrial Frequency Converter Acs880-01-246A-3

- Steel casting machine control cabinet

- Semiconductor Equipment Setcas KW-4BC Spin Coater

- Single Pass Honing Machine

- Isotech 4852 ADVANCED

- Wireless Pressure Transmitter

- Electrical Machine Trainer

- Additel ADT761

- Industrial Oil Separator and Filters

- Laser Bevel Cutting Machine