Automatic Desiccant Filling Machine for Insulating Glass - Wholesale Rate

Automatic Desiccant Filling Machine for Insulating Glass - Wholesale Rate

| Country of Origin | China |

| MOQ | 1 Sets |

| Price | USD 7250 / Sets |

| HS Code | 8464901900 |

| Category | Machinery & Industrial Supplies Construction Machinery |

Contact Automatic Desiccant Filling Machine supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

Automatic desiccant filling machine

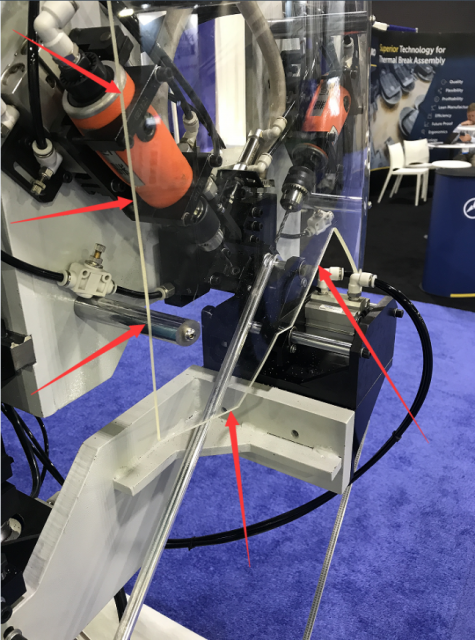

The Automatic Desiccant Filling Machine, from Jinan Lijiang Glass, is an important tool in the production of insulating glass. This advanced machine integrates multiple functions essential for manufacturing insulating glass. It drills holes in aluminum spacer frames, fills them with desiccant, and applies sealant, ensuring the integrity of the final product.

Equipped with a Germany Siemens control system, the machine delivers an efficient desiccant filling, which is crucial for maintaining the airtight properties of the insulating glass. Its adaptability allows it to handle various frame sizes, from a maximum of 2000mm by 2000mm to a minimum of 300mm by 250 mm and supports aluminum spacer sizes from 6A to 27A. The adjustable molecular sieve diameter ranges from 1mm to 1.5mm, enhancing its versatility.

The machine features a user-friendly interface with a touch screen for easy operation and adjustment. It includes an automatic loading and replenishing system for continuous desiccant supply, which streamlines the production process. The control over filling height and time further boosts efficiency and productivity.

Manufacturing Technique

Item.

Spec.

Filling aluminum frame’s maximum size

2000mm*2000mm

Filling aluminum frame’s minimal size

150*300mm

Article aluminum specifications

5.5-24mm

Air source

≥0.65MPa

Power supply and power consumption

AC220V 50Hz 1KW

Molecular sieve diameter needed

0.5-0.9mm

Dimension

1300mm*1100mm*3650mm

Total power

AC220/380V 50Hz 2.5KW

Dimension

10500mm*2200mm*2600mm

Name

Brand

PLC

German SIEMENS

Low voltage electrical apparatus

German SIEMENS

sensor

Korea AUTONICS

guide

Taiwan TBI

triplet

TAIWAN AIRTAC

Solenoid valve

TAIWAN AIRTAC

Gas driller

Taiwan BOA

Switch power

Taiwan TEND

GUIDE

Taiwan TBI

Solenoid valve

Taiwan AIRTAC

Sensor

KOREA AUTONICS

Advantages & Features

Main Feature

The filling height of can be adjusted according to the size of the spacer frame

Filling time can be adjusted

Desiccant auto loading and replenish

Auto drilling, filling, and sealing function

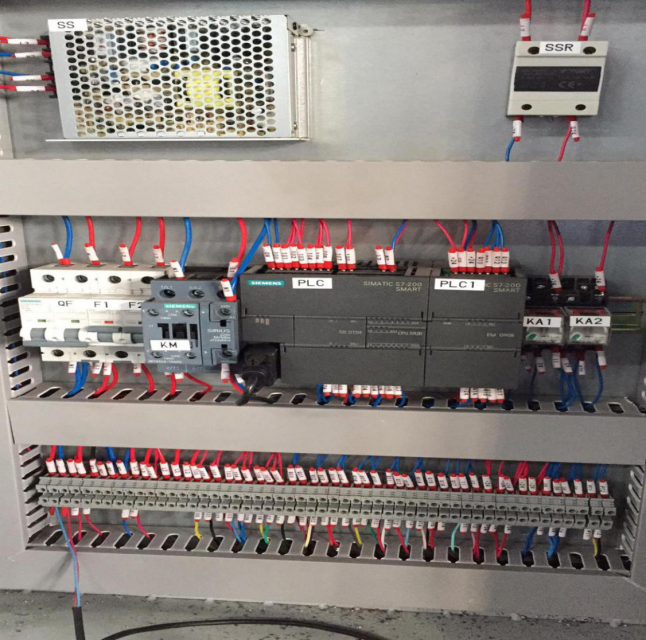

Germany Siemens PLC control system

Touching screen interface, simple and visible

Adding glue way is safe and easy

The machine can fill the arc frame.(optional function)

Can fill Molecular sieve diameter 0.5-0.9mm, 1.0mm-1.5mm(optional function)

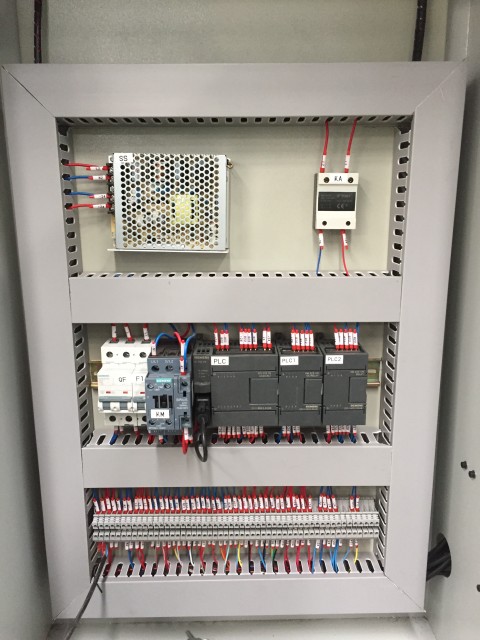

The Unique ID Code Number

All the electrical wires of the machine parts have the unique ID code number, it could match with specification, also it will make it easy for the communication with customers in the after-sales service on future.

The Touching Screen Interface

The touching screen interface, which the parts of the machine, is simple and visible; and also, the filling time could be adjusted according to the size of the spacer frame in the touch screen.

The Materials Bucket

The desiccant filling automatically loading from the materials bucket. (When the material was used up the sensor will alarming, desiccant will automatically loading.)

The Electrical Component

The electrical component is all German Brand-Siemens, which is adopted internationally renowned brands to ensure the stability of the equipment.

The machine promises durability and reliable performance. The inclusion of unique ID codes for electrical components facilitates effective after-sales support. With options for filling various molecular sieve diameters and handling arc frames, this machine represents a valuable investment for both small and large-scale glass manufacturing facilities.

| Packaging Info: | Wooden Cases Package and Container Transfer |

| Delivery Info: | Qingdao Port or Tianjin Port |

Product Specification

| Model No : | Green or Customers' Requirement |

| Material : | 1300mm*1100mm*3600mm |

| Max. filling aluminum frame : | 2000mm*2000mm |

| Min. filling aluminum frame : | 300mm*250mm |

| Min spacer frame : | 150-300mm |

| Aluminum spacer size : | 6A-27A |

| Molecular sieve Diameter : | 1-1.5mm |

| Air pressure : | 0.65mpa |

Product Usages

The Automatic Desiccant Filling Machine is used to enhance the production of insulating glass by performing critical tasks efficiently. It drills holes in aluminum spacer frames, fills them with desiccant, and applies sealant to ensure airtight insulation.

The machine’s precise control system allows for accurate desiccant filling, which is crucial for maintaining the quality of insulating glass. It is suitable for various frame sizes and types, including arc frames, making it a versatile tool in glass manufacturing.

Regular maintenance includes checking the desiccant loading system and adjusting the filling time as needed for optimal performance.

Product Keywords: automatic desiccant filling machine price, wholesale desiccant filling machine, desiccant filling machine supplier, insulating glass machinery, automatic desiccant filling equipment, bulk desiccant filling machine, B2B desiccant filling machine, China desiccant filling machine

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8615610xxxxx |

Supplier Info:

Jinan Lijiang Glass

Shandong Sheng, China

Shandong Sheng, China

Year Established: 2012

Business Type:

- Manufacturer

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Jinan Lijiang Glass

More Products From This Supplier

Related Products

-

- Price: USD 5000 / Piece

- MOQ: 1 Piece

-

- Price: USD 14.9 / Pieces

- MOQ: 500 Pieces

- Concrete pipe making Plant

- Hydraulic Outrigger Crawler Spider Crane

- Ring blower 4RB 420

- Porcelain Tiles and Ceramic Tiles

- EFEM/Sorter Wafer Transfer Module

- Builders Laser Level

- Sludge Screw Press Dewatering Machine for Landfill Leachate

- slew bearing

- Bitumen Boiler with Sprayer Machine

- PARMAR Brand Edge H Series Press Brake Heavy Duty

- Lepidolite Clinker Production Line

- 18.8kw Automatic Cutting System Brick Machine