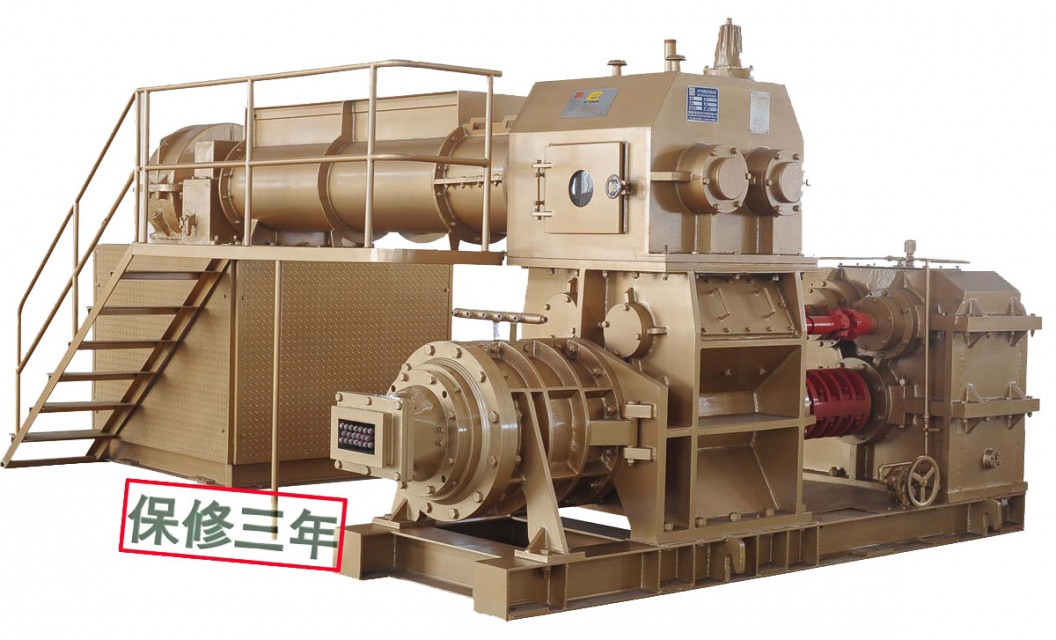

Brick Machine JKY55-55 Vacuum Extruder – High Capacity, Low Consumption

Brick Machine JKY55-55 Vacuum Extruder – High Capacity, Low Consumption

| Country of Origin | China |

| MOQ | 1 Sets |

| Price | USD 35000 / Sets |

| Category | Machinery & Industrial Supplies Construction Machinery |

Contact Brick Machine Jky55-55 Double-Stage Vacuum Extruder supplier for wholesale b2b price, customization or other inquiries

Post Buy Requirement

Get quick response from worldwide suppliers

Brick Machine Jky55-55 Double-Stage Vacuum Extruder (2 Mud-Strip Outle

The Brick Machine JKY55-55 Double-Stage Vacuum Extruder is designed to produce high-quality hollow bricks using a range of raw materials, including rock, coal gangue, and fly ash.

The machine features an independent all-steel structure and a universal joint connector, enhancing stability and extending service life through processes like quenching, tempering, and heat treatment. It is an excellent choice for medium-sized enterprises looking to transition to new wall materials.

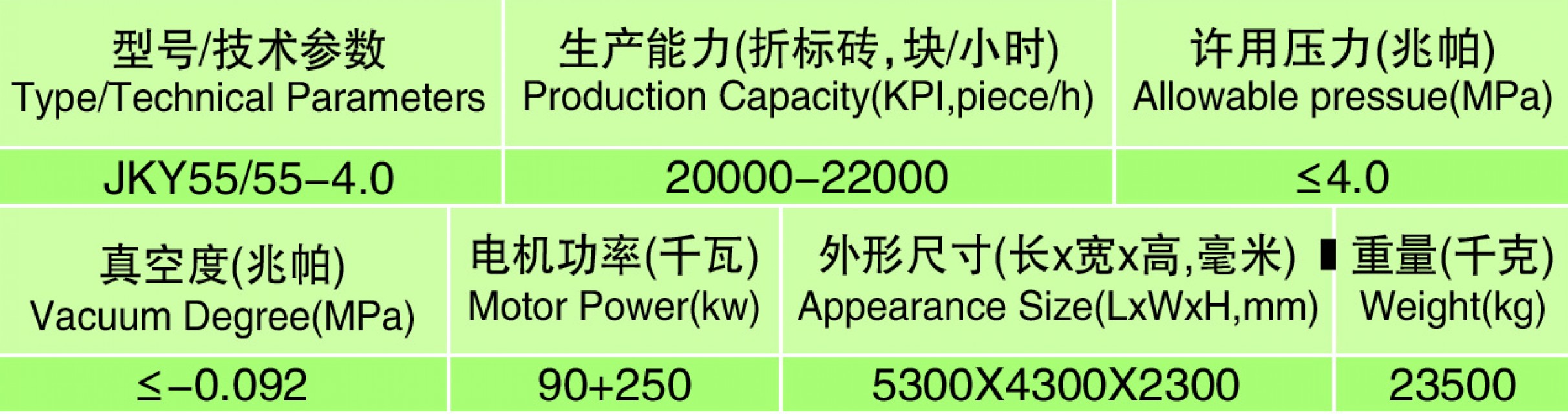

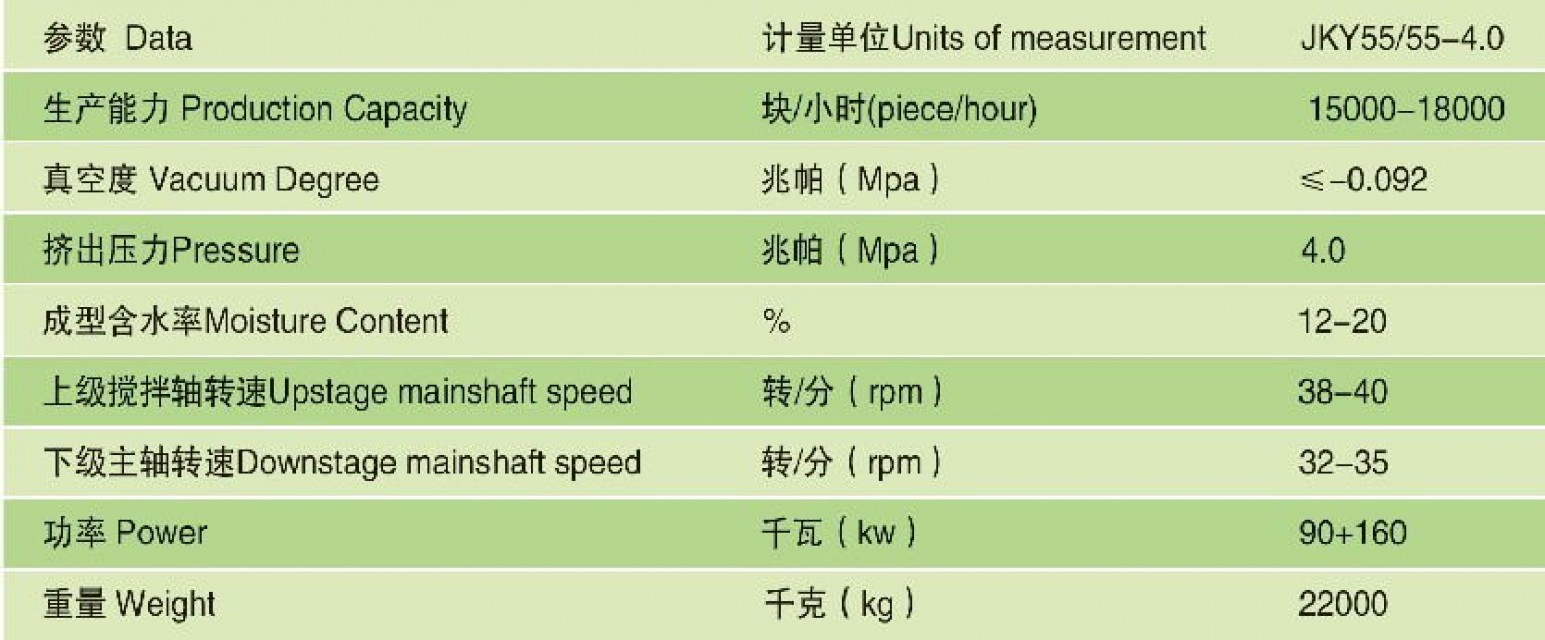

Technical Specifications:

- Type/Technical Parameters: JKY55/55-4.0

- Production Capacity (Pieces/h): 20,000-22,000

- Allowable Pressure (MPa): ≤4.0

- Vacuum Degree (MPa): ≤-0.092

- Motor Power (kW): 90+250

- Appearance Size (LxWxH) mm: 5300 x 4300 x 2300

- Weight (Kg): 23,500

Key Features:

- Manufacturer: Fujian New Oriental Machinery Co. Ltd.

- Brand Name: New Oriental

- Motto: "Be Careful & Be Meticulous, High Efficiency & Low Consumption, Pursuing Perfection & Satisfying Customers."

- Marketing System of New Oriental Machinery:

Testing on Raw Materials:

The raw materials for making bricks include clay, shale, coal gangue, fly ash, tailings, construction waste, river mud, and life sludge. Chemical composition analysis, physical properties, and moisture content of green bricks are essential factors in determining the suitability of raw materials for brick-making. These factors also influence process planning, equipment matching, kiln structure, and brick quality.

Overall Planning:

A comprehensive plan should be developed for a brick factory, covering raw material storage, manufacturing shops, finished product stacking, power control systems, office and living facilities, greenbelt, and lighting, all based on the local situation.

Management Rules:

Machines should be operated according to specifications and handbooks. Avoid overburdening the equipment. Emphasize training and daily maintenance. Regulate enterprise rules and employee behavior to ensure smooth production. Formulate company strategy planning and mission.

Kiln Structure:

The kiln structure and relevant equipment should be determined according to the process design. Focus on the quality of raw materials for heating engineering to ensure high-quality output from the kiln.

Choice of Equipment:

Equipment should be selected based on the process design, focusing on stability, progressiveness, service, and cost performance. Stability refers to the equipment's ability to function without issues for a certain period, depending on its texture, strength, structure, and fineness.

Process Design:

The process design is a comprehensive plan for raw materials processing, including crushing, aging, molding, storage of green bricks, drying, sintering, unloading, and packing.

| Payment Terms: | T/T, L/C |

| Packaging Info: | Packaged Into Container |

| Delivery Info: | Xiamen Port |

Product Usages

The Brick Machine JKY55-55 Double-Stage Vacuum Extruder is primarily used for producing high-quality hollow bricks from materials such as rock, coal gangue, and fly ash. It is suitable for medium-sized enterprises looking to upgrade their production facilities with efficient, low-maintenance equipment.

The machine's robust construction and advanced processing techniques ensure consistent output and long-term reliability, making it an essential asset for brick manufacturing operations.

Product Keywords: Brick machine vacuum extruder supplier, JKY55-55 extruder wholesale rate, double-stage vacuum extruder manufacturer, hollow brick extruder price, brick machine exporter China, vacuum extruder bulk supplier, construction machinery wholesale rates, B2B brick machine supplier

Product Images

Supplier Info

| Company Name | : | |

| Business Type | : |

|

| Supplier Phone: | : | +8613959xxxxx |

Supplier Info:

Fujian New Oriental Machinery Co. Ltd.

Fujian, China

Fujian, China

Year Established: 1993

Business Type:

- Manufacturer

- Exporter

Contact Supplier About This Product

Contact Supplier for product pricing, customization or other inquiries

Send Your Message to: Fujian New Oriental Machinery Co. Ltd.

More Products From This Supplier

Related Products

-

- Price: USD 5000 / Piece

- MOQ: 1 Piece

-

- Price: USD 1369 / Piece

- MOQ: 1 Piece

-

- Price: USD 19.9 / Pieces

- MOQ: 500 Pieces

- Shelf Electrostatic Coating Line

- 6-way 7-12 Grading Blade

- Industrial Dust Collector

- Top Feed Vibroflot

- Honeycomb & Hollow Core Metal Composite Panel Production Line

- Trailer Diesel Concrete Pump

- ESCO Excavator Bucket Teeth

- ADB 1400 Rock Breaker Excavator Hammer Hydraulic Breaker

- CONELE Planetary Concrete Mixer

- Concrete pipe making Plant

- Ring blower 4RB 420

- Wafer Vacuum Transfer Module (VTM300)